A Cross Stream Sampler is an automated sampling solution used for representative sampling of a flowing stream of bulk material, such as a conveyor belt, a chute, or a pipe. It works by diverting a portion of the material stream through a separate channel where a sample can be taken.

The cross stream sampler typically uses a cutting blade or a gate to divert a portion of the material stream, and a conveyor or other device to transport the sample away from the main flow for further analysis or processing. The analysis of particle size and shape can be automated with e.g. Camsizer Online 30.

Cross stream samplers are commonly used in industries such as mining, agriculture, and manufacturing to ensure accurate and representative samples of raw materials and finished products. They are particularly useful for materials that are difficult to extract a sample from while they are flowing, as they allow for continuous sampling without disrupting the flow of the material.

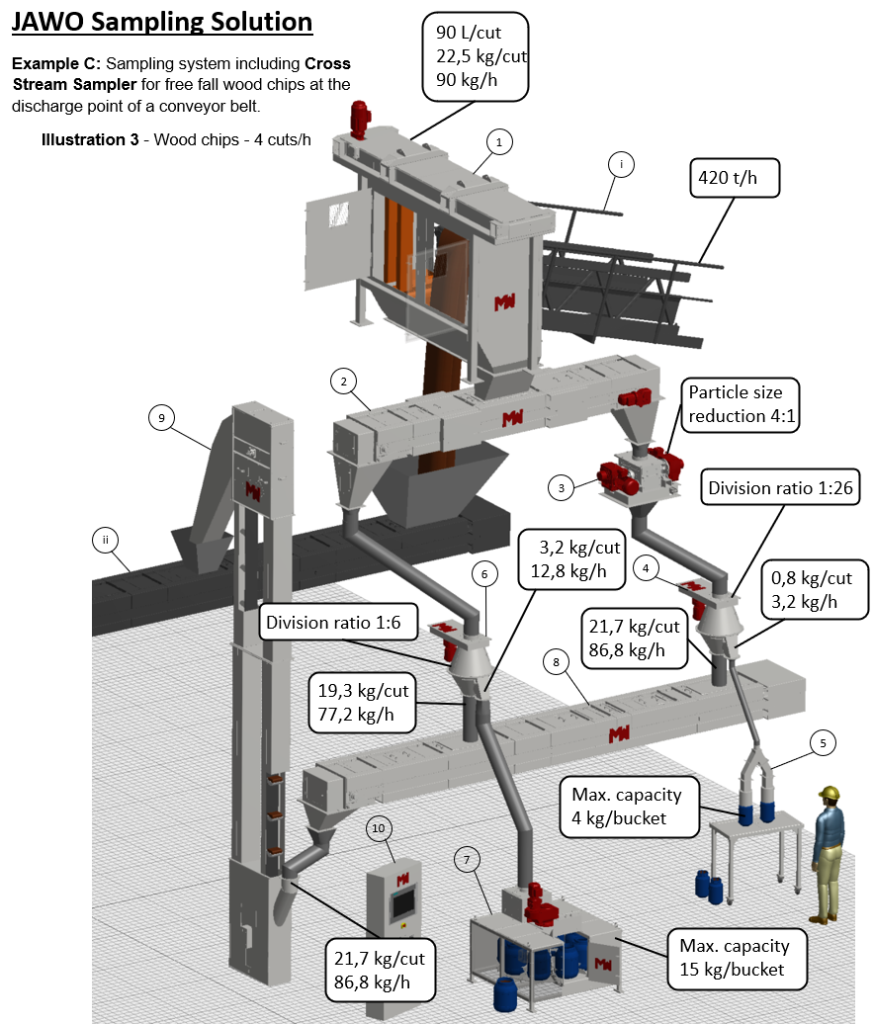

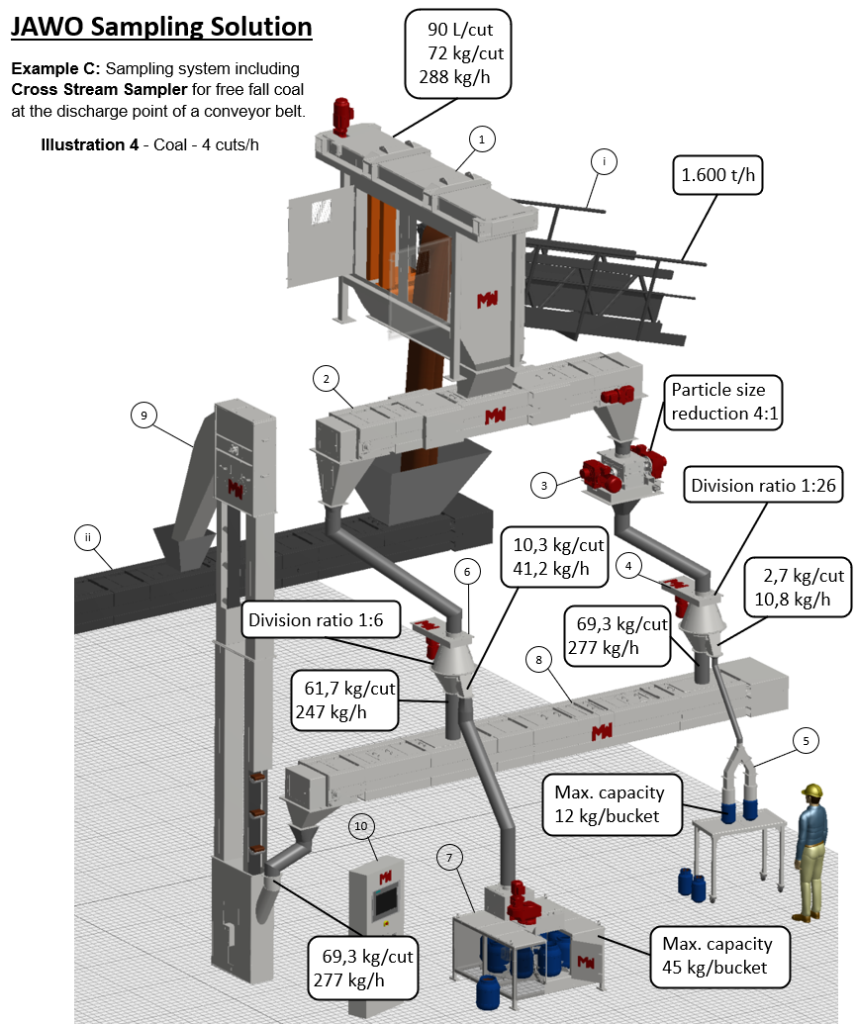

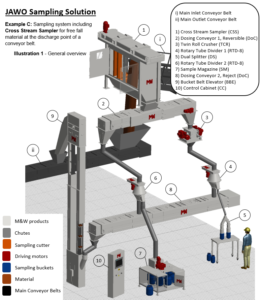

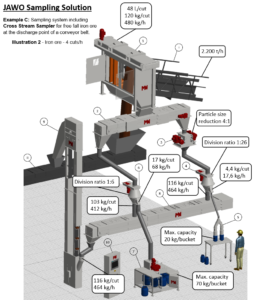

Solution description

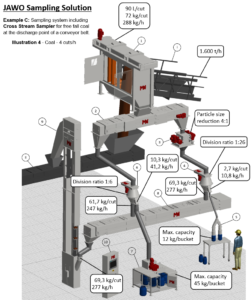

- The Cross Stream Sampler (CSS) extracts a representative increment/cut of bulk material from a free-falling stream at the discharge point of a conveyor belt. Representativity of the increment is ensured by extraction of a complete cross section of the material stream.The sampling outlet of the CSS is connected to a Reversible Dosing Conveyor.

- The Reversible Dosing Conveyor (DoC) is used to transport and/or dispense the bulk material by a belt. Depending on the usage of the representative sample of the material the DoC dispenses to either the Twin Roll Crusher (3) or the Rotary Tube Divider (6), which are connected by chutes. The DoC has a design, which ensures a minimum of spillage and a correct dosing.The DoC dispenses the material into a chute, which is connected to a Rotary Tube Divider.

- The Twin Roll Crusher (TCR) is designed for particle size reduction of bulk material by crushing the material. The crushing characteristics can be adjusted by changing the distance between the rolls.The outlet of the TCR is connected to a Rotary Tube Divider by a chute.

- The Rotary Tube Divider 1 (RTD) is designed for a representative division of bulk material. The RTD splits the material stream into A) a sub-sample and B) a reject stream. The reject stream is connected to a DoC (8) by a chute.The sub-sample outlet of the RTD is connected to a Dual Splitter by a chute.

- The Dual Splitter (DS) is used for splitting the bulk material into two buckets. The material can be split in the ratio 25-75% or directed 100% to either the left or the right bucket. The position of a dual-direction flap splits or leads the material flow to the buckets.

- Rotary Tube Divider 2 (RTD) is used to make a representative division of the bulk material and leads it into a Sample Magazine. The reject stream is led to the DoC (8) by a chute.

- The Sample Magazine (SM) is designed to automatically fill sample buckets with representative samples of bulk material thereby ensuring a composite sample. The SM acts as a storage device since it has multiple buckets installed inside on a carousel. The SM is designed to prevent contamination and moisture gain and loss of the gathered samples.

- The Dosing Conveyor (DoC) transports the reject stream of bulk material from the RTD (4) and RTD (6) into a chute which is connected to a Bucket Belt Elevator.

- The Bucket Belt Elevator (BBE) lifts the reject stream to the main outlet conveyor belt by means of buckets. The buckets are attached to a belt, which pulls them around.

- All the above equipment requires a Control Cabinet (CC) that controls, powers and protects the JAWO Sampling machines. The CC is also the interface for the operator and can serve as a junction box for all power and signal cables.