Introducing M&W Current Leads

Providing and Designing Multistage Current Leads for 20+ Years

Providing and Designing Multistage Current Leads for 20+ Years

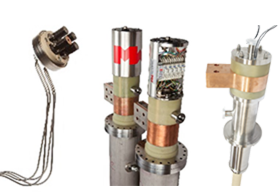

M&W Current Leads offers customers a range of well-proven superconduction current leads designs, optimised towards current, heat leak, coolant types and application.

We offer our customers access to 20+ years of experience and a network of specialists and likeminded people. You can learn more about Mark & Wedell, our history and how we operate as a business here: About M&W.

M&W Current Leads takes full ownership of the entire process starting with concept, design, engineering, production, FAT and thorough documentation.

A project can be the development of a prototype, a small series, or a high-volume production.

Our commitment is always the same:

In addition to unparalleled quality, you get optimised current leads that will serve your installation well and be in operation for years to come.

The Big Science market consists of large research facilities, scientific test centres and is often funded by governments or groups of governments. In many scientific fields, major progress is only achieved through Big Science facilities, which are needed to perform exotic experiments.

The unique mechanical and electrical engineering competences and high level of craftsmanship of M&W Big Science enables us to offer products and solutions to the demanding customer base, where quality, durability and precision is key.

M&W Current Leads Brochure

Contact information – Multistage Current Leads.

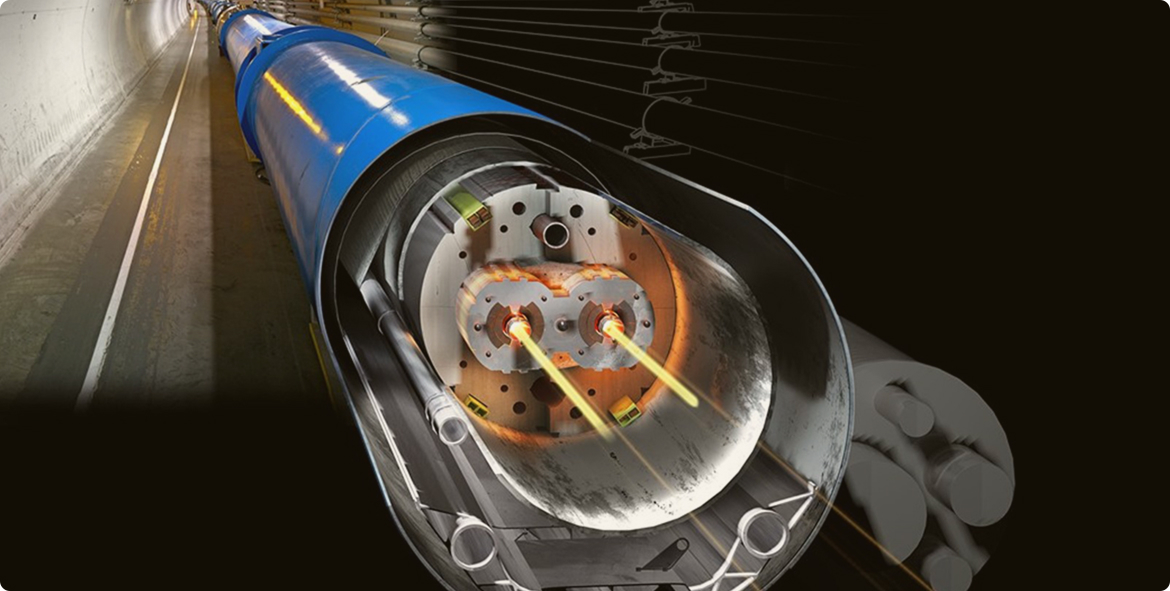

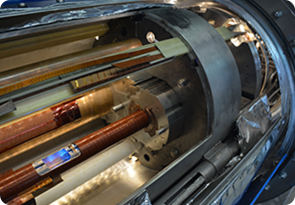

100 meters below ground in a 27 km long ring, particles are being accelerated clock-wise and counter clock-wise via current leads.

- Each beam contains 3.000 ‘bunches’ of particles, with 100 billion particles in each bunch.

- When two bunches collides, only about 40 particles that crash head-on.

- 1 billion particle crashes happen every second.

- The velocity of the proton beams reaches 99,9999991% of the speed of light in the LHC which makes them revolve 11.245 times each second.

- The energy of the accelerated protons is 6,5 TeV, yielding collisions of 13 TeV in the desired head-on collision.

M&W Current Leads Delivers Optimised Superconducting Current Leads.

- The CERN facility has about 10 accelerators that have been built gradually over the last 50 years.

- The LHC is built in tunnels previously used for the Large Electron-Positron Collider, which was dismantled in 2001.

- Mark & Wedell has delivered current leads to CERN with currents ranging from 60 A – 13.000 A.

- One of Mark & Wedell’s most prominent deliveries to the LHC was 410 current leads for ‘corrector’ dipole magnets, used for keeping the LHC particle beam under control.

- Furthermore current leads with varying operating currents have been delivered to CERN, mostly for magnet testing purposes.

- The power consumption of the LHC in full operation is equivalent to the power production of seven 10 MW wind turbines in full operation.

- 1.232 bending dipole magnets direct the particle beams around the circular accelerator.

- Each dipole magnet has a magnetic field of 8,33 T, and is kept at a temperature of 1,9 K, which is colder than outer space!

- The dipole magnets are 15 m long and weigh around 35 t each.

The Large Hadron Collider (LHC) is the world’s largest and most powerful particle accelerator and the largest scientific test instrument ever built. The collider is a 27 km long circular accelerator placed 100 m underground. The particles are accelerated in 2 independent vacuum tubes, with one beam traveling clock-wise and one beam traveling counter clock-wise.

The particle accelerators accelerate protons and other particles to near the speed of light, before smashing them together at so-called collision points. This is done in order to study the fundamental interactions of nature. The LHC was built to test the Standard Model of particle physics: a classification of all known elementary particles – the building blocks of the world around us. In 2012 the LHC confirmed the detection of the Higgs Boson, which was predicted in 1964. Mark & Wedell has so far developed and supplied CERN with more than 450 superconducting current leads units.

Current Leads Type CVHH Suitable for Currents above 10.000 A

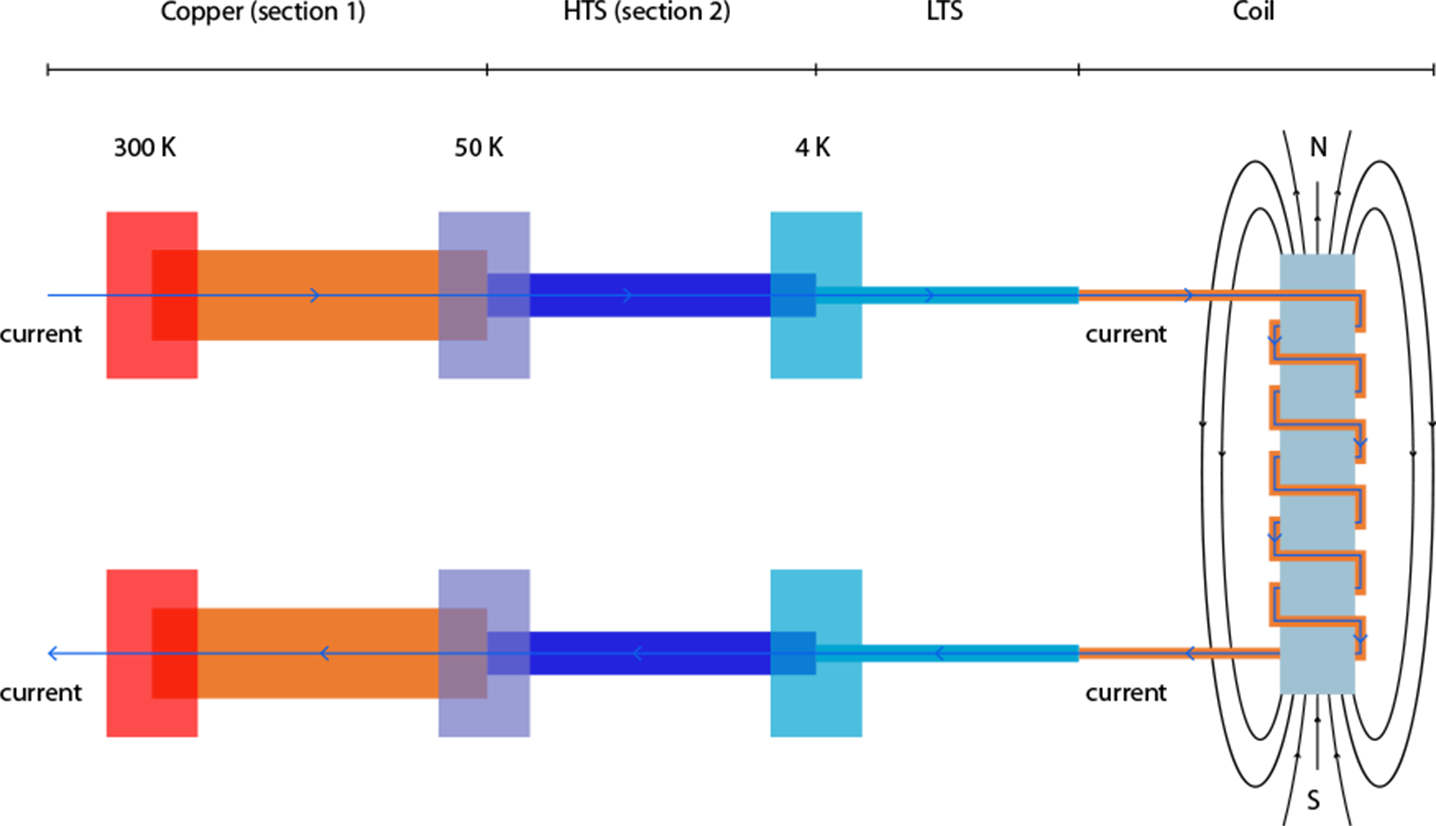

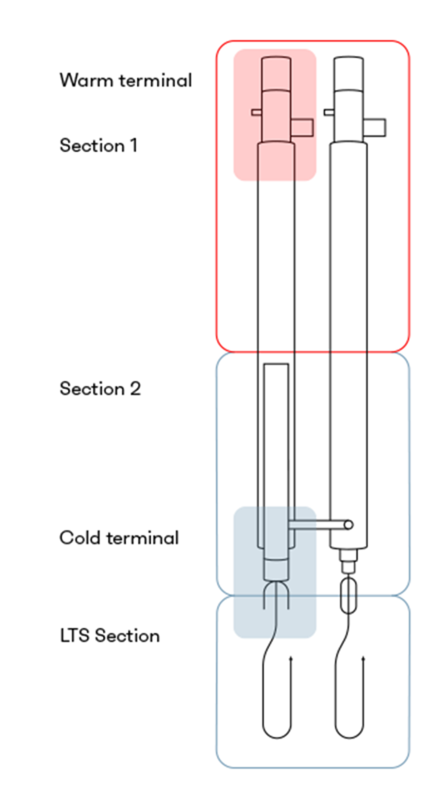

This principal sketch illustrates a M&W current leads type CvHH that is suitable for currents above 10.000 A. The current enters the warm terminal and exits at the cold terminal. The current leads consists of different sections where different materials and coolants are used.

Bridging Big Science and Industries for 20+ years.

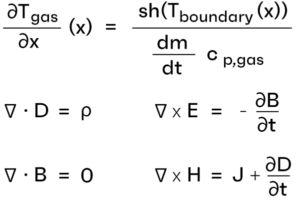

Theory of Thermodynamics and Electromagnetism

Products

Superconducting Electromagnet

The bridge between the warm and the cold terminal.

Current leads are a key component in any superconductor technology. It leads the current from the ambient temperature of 20 ⁰C to the cold environment where the superconducting wires are operated. The superconductor must be cooled to cryogenic temperatures, which for low temperature superconductors is around 4 K (-269 ⁰C). At this temperature, the superconductor enters its superconducting state and has no electrical resistance.

Particle accelerators use strong magnetic fields either to bend or to focus/de-focus the particle beams. To create such a strong magnetic field, strong superconducting electromagnets are required. These magnets rely on thin superconducting wires that can carry huge electrical currents, thanks to zero resistance, and can thus create very strong magnetic fields, in the range 1-10 T. Thousands of amps are entering the current leads through the warm terminal that consists of a massive copper block and exits through the cold terminal in a tiny superconducting wire.

In the following you will see how this transition between the large copper conductor at the warm terminal and the small superconductor at the cold terminal looks like.

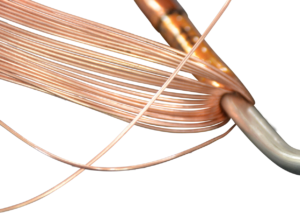

Copper wires: the problem

When an electrical current passes through for instance a copper wire, the wire will heat up. This is due to thermal losses in the wire coming from the electrical resistance in the copper. If the wire surroundings cannot keep the material below a certain temperature, the wire will overheat and eventually melt-down. Therefore there is a limit to how much current any given copper wire can lead. The image on the left shows copper wires connected to the warm end of a current leads, and the copper wires are capable of carrying 15.000 A.

A thicker copper wire can of course carry more current, but the thousands of amps required to create the strong magnetic field required in particle accelerators, would make the copper cable too thick and impractical, and at the same time generate a lot of thermal losses.

Superconducting wires: the solution

Some materials lose their electrical resistance at low temperatures. These materials are called superconductors and they do not have any ohmic losses when an electrical current is passing through them. This makes superconductors ideal as conductors in electromagnets where huge magnetic fields shall be achieved. The image on the left shows Niobium-Titanium wires, also capable of carrying 15.000 A. The current density in these wires is 4-500 times larger than the current density of similar copper wires.

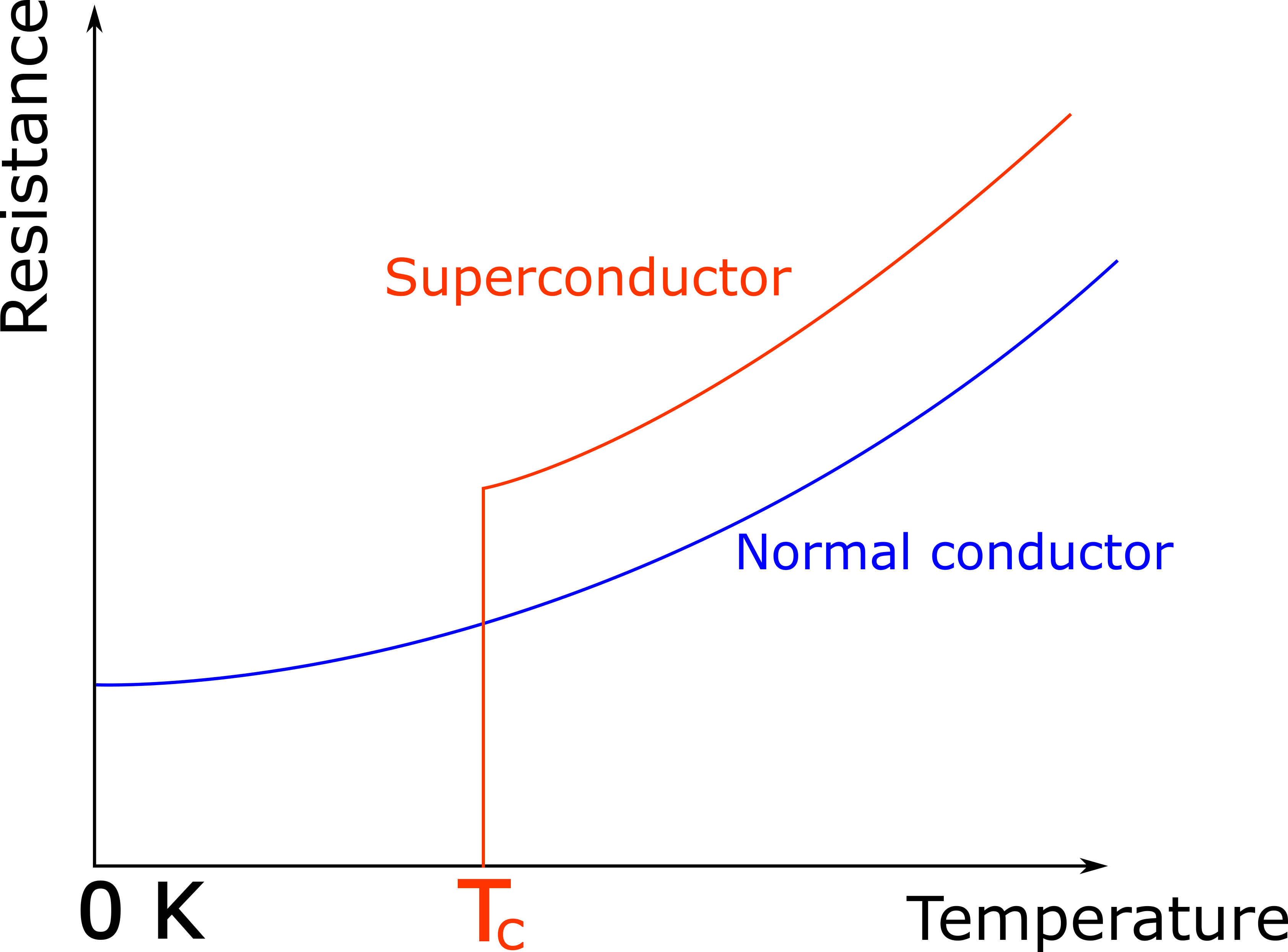

Superconducting materials become superconducting below a certain transition temperature, also called critical temperature Tc, whereas non-superconducting materials still have a finite resistance, even at 0 K (-273 ⁰C). The resistance of these two types of materials is shown in the following figure, where the resistance as a function of temperature is illustrated.

The superconducting state of the material also depends on the applied magnetic field and the current, but in most applications, the superconductor supports a current density which is hundreds of times larger than that of copper wires.

Known superconductors and the search for new ones

Scientists keep discovering new types of superconductors, and superconductors with a high transition temperature are highly sought-after. Some of the recent discoveries include superconductors with transition temperatures at almost room temperature, but only under extreme conditions, such as a pressure of 155 GPa! [Click to enhance graph]

The Technology behind Superconducting Current Leads our superconducting current leads.

Current leads come in many shapes and forms depending on the specification and applications. There are many considerations to take into account when designing a current lead.

- 1

- 2

- 1

- 2

- 1

- 1

- 2

- 3

- 1

- 2

- 1

- 2

- 3

- 1

What is the operating current?

The typical operating current is from a few hundred to tens of thousands of amps. The current density changes dramatically through the current leads. For a 12 kA CL, for instance:

- The normal conducting warm terminal can have a cross section of 40 cm2 and a current density of 300 A/cm2

- The superconducting cable at the cold terminal can have a cross section of 0,10 cm2 and a current density 125.000 A/cm2

Thus the current density is increased with a factor of about 400.

WHICH COOLANT TYPES CAN BE USED?

- For example in section 1, liquid nitrogen and its boil-offs can be used as coolants. The interception point (the point where section 1 and 2 meet) must be kept below the critical transition temperature of the HTS material, which is above the boiling point of liquid nitrogen (77 K). This makes nitrogen an ideal coolant for this section.

- At the cold end liquid helium is used and the boiled off gaseous helium is used as coolant in section 2. Most LTS materials become superconducting below 10-15 K. Liquid Helium temperature is around 4 K, and is thus an ideal coolant at the cold terminal.

WHAT ARE THE SPATIAL DIMENSIONS OF A CL?

- At low current the size does not have to be more than the size of a walking stick. For very high current it can be 2 metres long, 30 cm in diameter and weigh 150+ kg.

WHAT TEMPERATURE IS THE CURRENT LEADS OPERATED AT?

- The warm end of the current leads is kept at room temperature (300 K).

- The current leads are sometimes anchored at an intermediate temperature (typically 50-80 K) in the middle.

- The cold terminal is typically cooled by liquid helium to a temperature of around 2-4 K.

WHAT IS THE TYPICAL LHE CONSUMPTION?

The coolant consumption depends very much on the application and the operational conditions.

- If the CL is only used for a couple of tests a year, a simple helium based CL would suffice (CvH) . Then a 10 kA CL consumes about 35 litres liquid helium per hour.

- If however the CL is used in multiple and/or continuously running experiments, a more advanced solution using HTS and Nitrogen as additional coolant (CvHNH) is ideal. In this case the liquid Helium consumption for a 10 kA CL would be reduced to less than 2 litres per hour. About 15 litres of liquid nitrogen per hour would then also be required.

WHAT KIND OF MATERIALS IS A CL MADE OF?

- The normal conducting part (section 1) of any of our current leads will consist of high quality copper.

- The HTS part (section 2) of our current leads could for instance consist of BSCCO (bisko) or REBCO materials. Additionally, high grade stainless steel is used as support structure and quench protection.

- The LTS part of our current leads could for instance consist of NbTi.

WHAT KIND OF MEASURING EQUIPMENT CAN BE INSTALLED?

- Our current leads are normally fitted with multiple sensors for voltages and temperatures measurements. In addition heating elements are installed in the warm terminal.