Sampling Made Simple.

Introducing M&W JAWO Sampling.

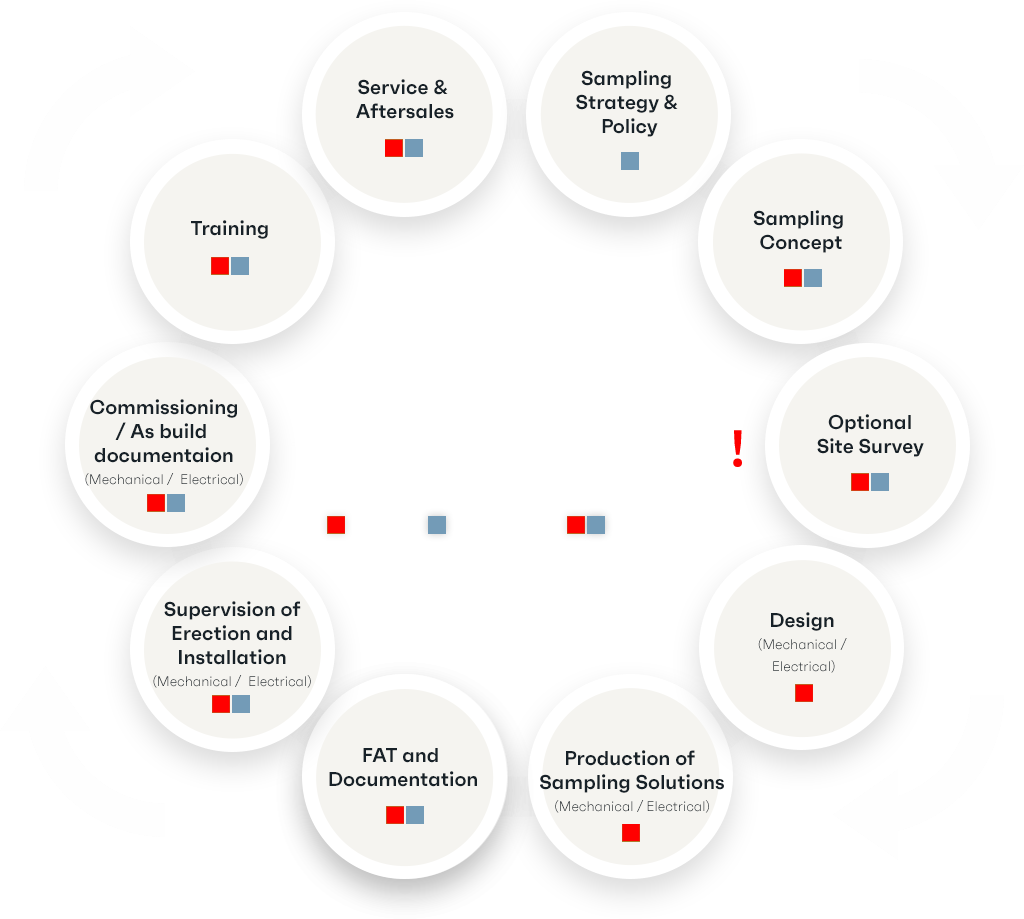

M&W JAWO Sampling offers customers a full range of automated and customized machines, instruments, and complete systems for representative sampling of bulk material, powder, and dust particles for a wide variety of industries.

Obtaining representative samples of the total lot before analysis is crucial – otherwise, there is little point in having made significant investments in laboratory equipment and analytical competencies.

What’s in it for you?

By operating our automated sampling solutions you are getting reliable knowledge about the properties of the material you buy, sell or produce enabling you to:

- Calculate the correct amount or value for each batch of material you receive or deliver – thereby reducing the risk of either overpaying or underselling

- For customers where larger or more expensive quantities of material are bought or sold, the economic impact of ensuring representative and consistent samples will be substantial.

- Confirm that you receive or sell products that meet contract requirements

- Monitor and optimize your production and quality control process

- Improve your mixing and blending operations to obtain better end-products

- Estimate the type and amounts of by-products from your processed or manufactured batches

- Document the environmental impact and/or pollution from your production

- By buying the right sampling solution you are likely to save a lot of money.

M&W JAWO Sampling Brochure – English version

M&W JAWO Sampling Brochure – Spanish version

M&W JAWO Sampling Brochure – French version

Sampling made simple for 40 years.

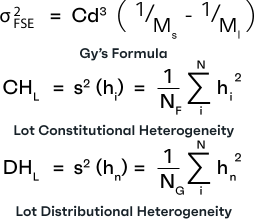

Theory of sampling

Standards

Customised solutions

Consistent, representative samples

You will be assured sampling solutions which produce consistent samples for your quality analysis – accurately and precisely representing the total lot from which it was collected.

As a result you get unbiased and reproduceable samples for international commodities such as aluminium, ash, bauxite, biomass, building materials, calcium, cement and cement clinker, coal, coke, copper concentrate, chromite ore, electro scrap, fertilizer, grain, granulates, iron ore/sinter/pellets, gold, industrial powders, lignite, limestone, heavy mineral sands, quartz, platinum, pot ash, rock salt, silicon and solid chemicals.

A global pioneer

M&W JAWO Sampling is one of the global pioneers in the development and production of automated sampling equipment, instruments and whole system solutions since 1982. Read much more about Mark & Wedell here.

In 1999 Mark & Wedell acquired FLS JAWO Handling from FLSmidth and continued developing a range of specific sampling products. In 2019 Mark & Wedell integrated “M&W Asketeknik” (extraction samplers and instruments primarily for the power and heat industry) into the M&W JAWO Sampling business unit.

Customer’s overall objectives are met by M&W JAWO Sampling.

Ensures correct pricing of bulk materials (buying and selling)

Quality control of traded goods and compliance with contracts

Increase of operational efficiency and check of regulatory requirements

International material standards

M&W JAWO Sampling equipment and sampling systems operate in accordance with approved international material standards such as ISO, ASTM, GOST, EN as well as DS3077 (2013).

All sampling equipment and solutions aim for compliance with the principles laid down in the Theory of Sampling (TOS) and gives you reliable knowledge of the material properties of your sample such as:

- Content grade

- Moisture content

- Mineral proportions

- Contamination

- Hardness

- Particle Size Distribution

Where are sampling solutions implemented?

M&W JAWO Sampling has supplied more than 3,000 automated sampling solutions to more than 950 projects in 85+ countries within the mining, mineral processing & metals refining, oil & gas, power and heat generation, cement, fertilizer, recycling and waste handling, building materials, food and pharma sectors.