Bucket samplers are commonly used in industries such as mining, agriculture, and manufacturing to ensure accurate and representative samples of raw materials and finished products.

They are particularly useful for materials with a high content of dust, as they are designed to minimize the effects of dust on the sample. It is designed to extract increments/cuts from a free-falling flow of bulk material in a vertical duct, ensuring representativity by collecting a complete cross section of the material.

To ensure a representative sample of bulk material, especially for materials with a high content of dust, the Bucket Sampler is the answer.

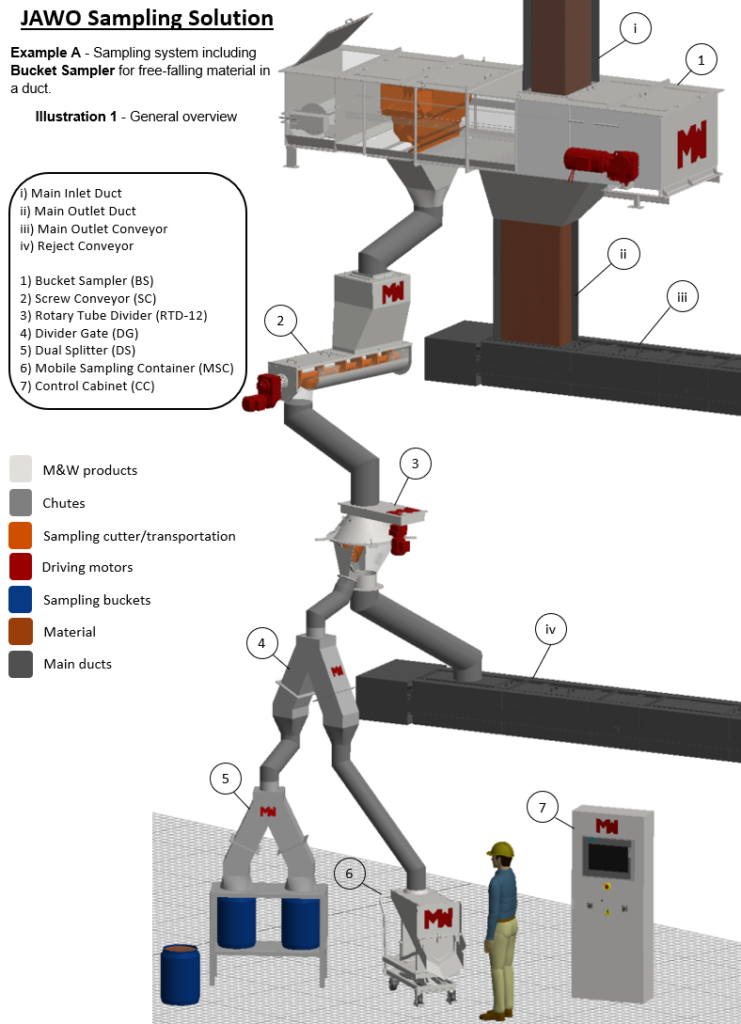

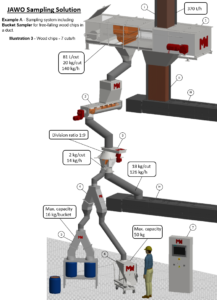

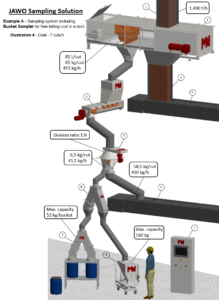

Solution description

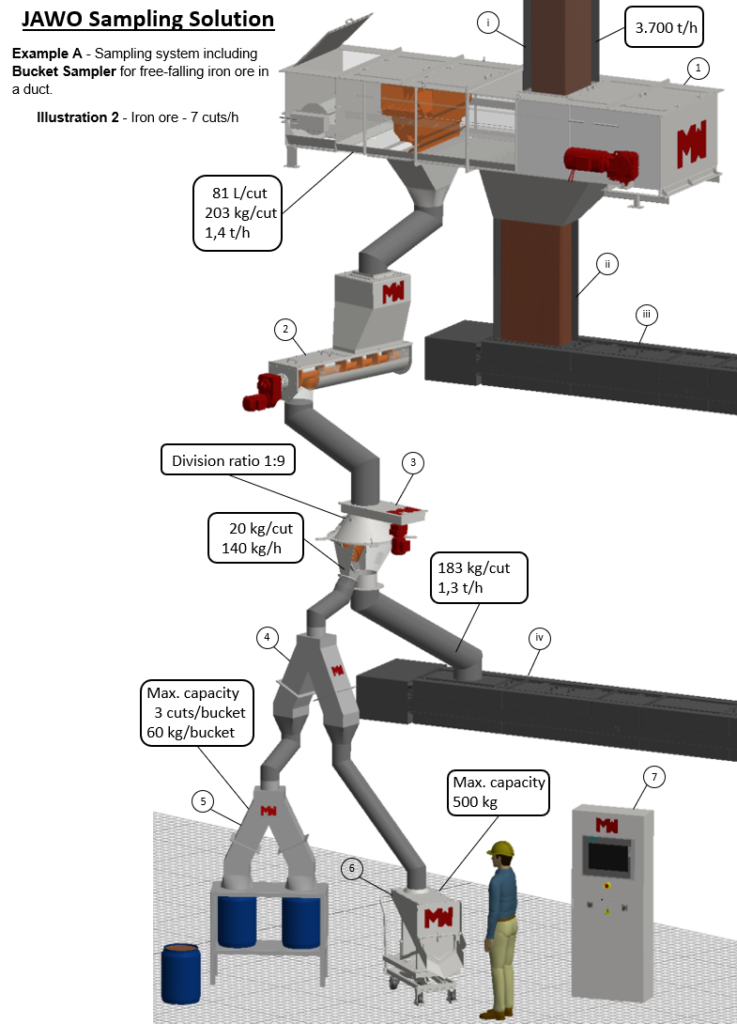

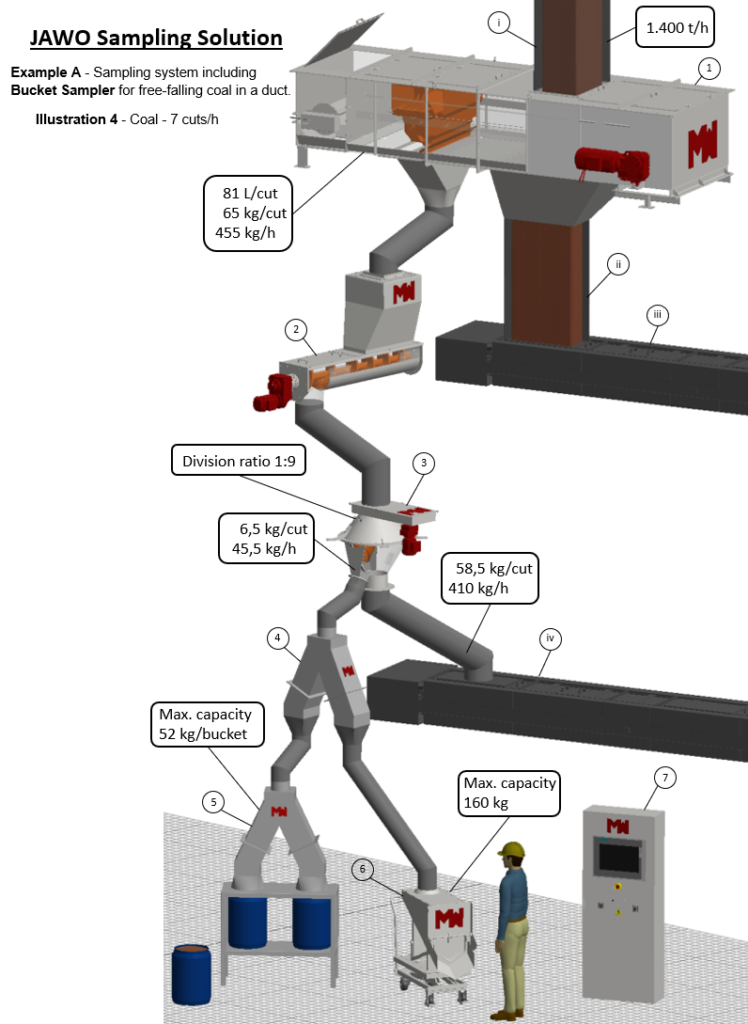

- The Bucket Sampler (BS) is designed to extract increments/cuts from a free-falling flow of bulk material in a vertical duct. Representativity is ensured since a complete cross section of the material is collected. The sampling outlet of the BS is connected to a Screw Conveyor by a chute.

- The Screw Conveyor (SC) is used to transport and/or dispense the bulk material by rotation of a screw.The SC dispenses the material into a chute, which is connected to a Rotary Tube Divider.

- The Rotary Tube Divider (RTD) is designed for representative division of bulk material. The RTD splits the material stream into A) a sub-sample and B) a reject stream. By a chute the reject stream is transported to a reject conveyor. The sub-sample outlet of the RTD is connected to a Divider Gate by a chute.

- The Divider Gate (DG) is used for directing the representative material either to the Dual Splitter (5) or the Mobile Sampling Container (6) by chutes. The position of a dual-direction flap leads the material flow to either (5) or (6).

- The Dual Splitter (DS) is used for splitting the bulk material into two buckets. The material can be split in the ratio 25-75% or directed 100% to either the left or the right bucket. The position of a dual-direction flap splits or leads the material flow to the buckets.

- The Mobile Sample Container (MSC) is designed to receive up to 200L of representative sampled material. Without any manual lifting the representative sample is easy to move around and unload.

- All the above equipment requires a Control Cabinet (CC) that controls, powers and protects the JAWO Sampling machines. The CC is also the interface for the operator and can serve as a junction box for all power and signal cables.