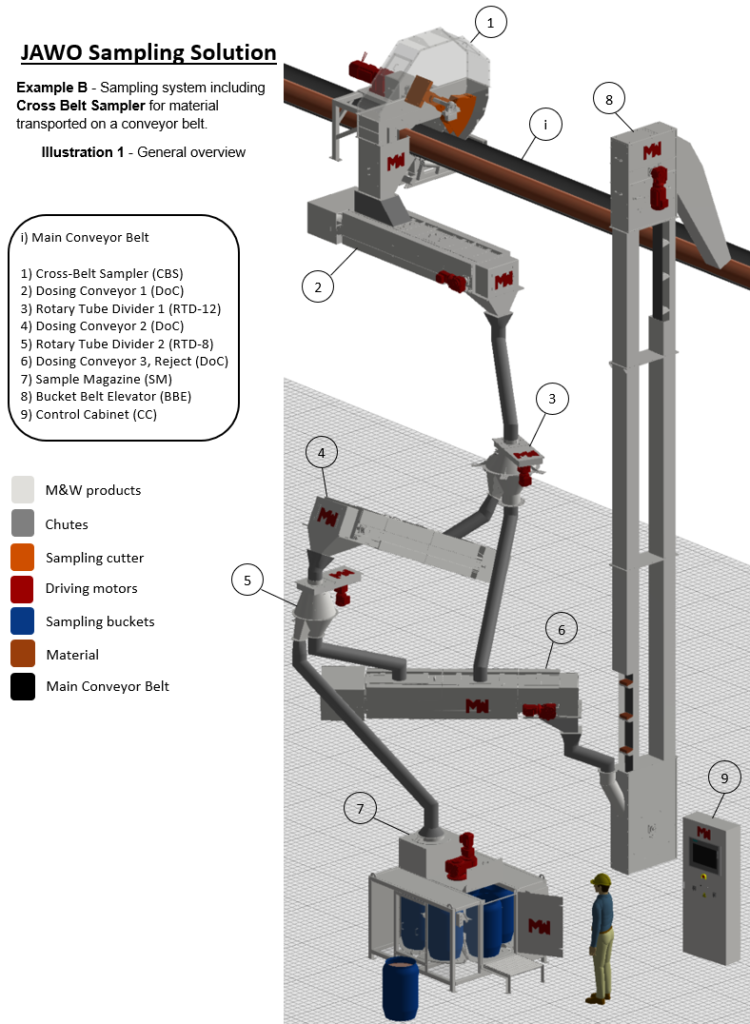

JAWO Sampling Solution – Cross Belt Sampler

How to do representative sampling of bulk material from a conveyor belt?

To ensure representative sampling of bulk material from a conveyor belt, a Cross Belt Sampling System is the solution.

Download the Cross Belt Sampler Solution brochure here

Solution description

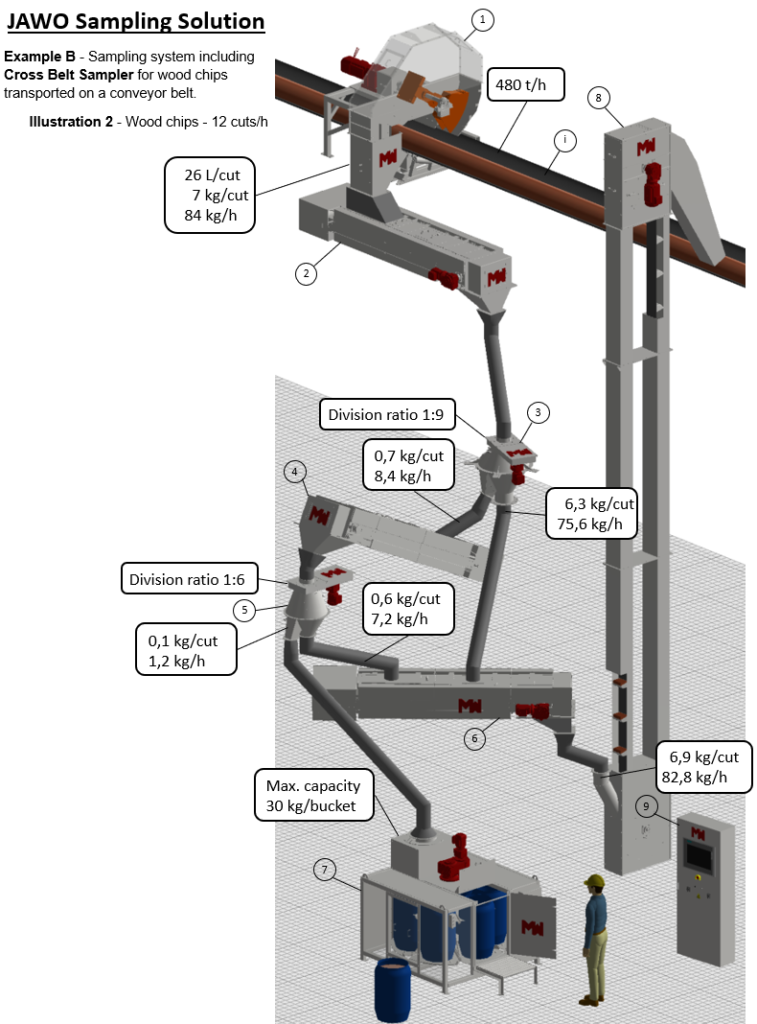

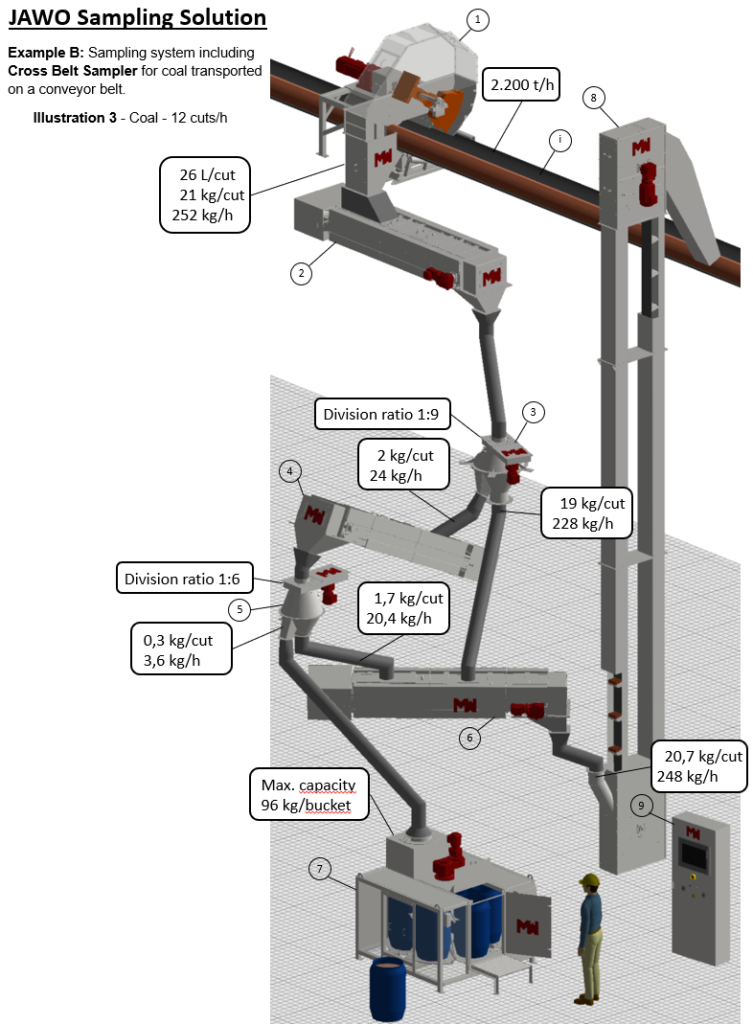

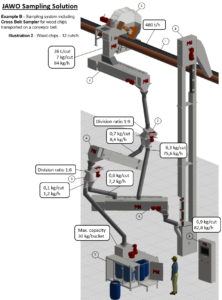

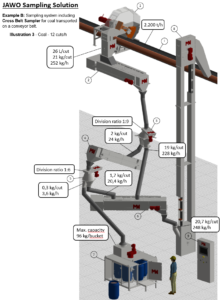

- The Cross Belt Sampler (CBS) is designed to extract increments/cuts from bulk material being transported on a conveyor belt. A representative increment is scooped into the sampling outlet from the conveyor belt in a circular motion by rotation of a sample cutter.

The sampling outlet of the CBS is connected to a Dosing Conveyor by a chute.

- The Dosing Conveyor 1 (DoC) is used to transport and/or dispense the bulk material by a belt. The DoC has a design, which ensures minimum spillage of the material and a correct dosing.

The DoC dispenses the material into a chute, which is connected to a Rotary Tube Divider.

- The Rotary Tube Divider 1 (RTD-12) is designed for a representative division of bulk material. The RTD splits the material stream into A) a sub-sample and B) a reject stream. The reject stream is connected to a DoC (6) by a chute.

The sub-sample outlet of the RTD is connected to a second Dosing Conveyor by a chute.

- The Dosing Conveyor 2 (DoC) transports and/or dispenses the sub-sample outlet from the RTD-12 (3) to a second Rotary Tube Divider by a chute.

- The Rotary Tube Divider 2 (RTD-8) divides the sub-sample from RTD-12 even further with the same representative division mechanism as for the RTD-12. The reject stream is connected to the DoC (6) by a chute.

The sub-sample outlet of the RTD is connected to a Sample Magazine by a chute.

- The Dosing Conveyor 3 (DoC) transports and/or dispenses the reject stream of bulk material from the RTD-12 (3) and RTD-8 (5) to the Bucket Belt Elevator by a chute.

- The Sample Magazine (SM) is designed to automatically fill sample buckets with representative samples of bulk material thereby ensuring a composite sample. The SM acts as a storage device since it has multiple buckets installed inside on a carousel. The SM is designed to prevent contamination and moisture gain and loss of the gathered samples.

- The Bucket Belt Elevator (BBE) lifts the reject stream back to the main conveyor belt by means of buckets. The buckets are attached to a belt that pulls them around.

- All the above equipment requires a Control Cabinet (CC) that controls, powers and protects the JAWO Sampling machines. The CC is also the interface for the operator and can serve as a junction box for all power and signal cables.

More about the Cross Stream Sampler from JAWO Sampling

A Cross Belt Sampler is a device used for representative sampling of a moving conveyor belt carrying bulk material. It works by extracting a sample increment from the belt as it passes by a sampling point, without interrupting the flow of the material. The cross belt sampler is positioned perpendicular to the flow of the material and uses a cutting blade to collect a sample of the material passing by. The sample is then conveyed away from the belt for further analysis or processing.

M&Ws JAWO Sampling Cross Belt Sampling Systems are commonly used in industries such as mining, agriculture, and manufacturing to ensure accurate and representative samples of raw materials and finished products. They are particularly useful for materials that are difficult to extract a sample from while they are flowing, as they allow for continuous sampling without disrupting the flow of the material.