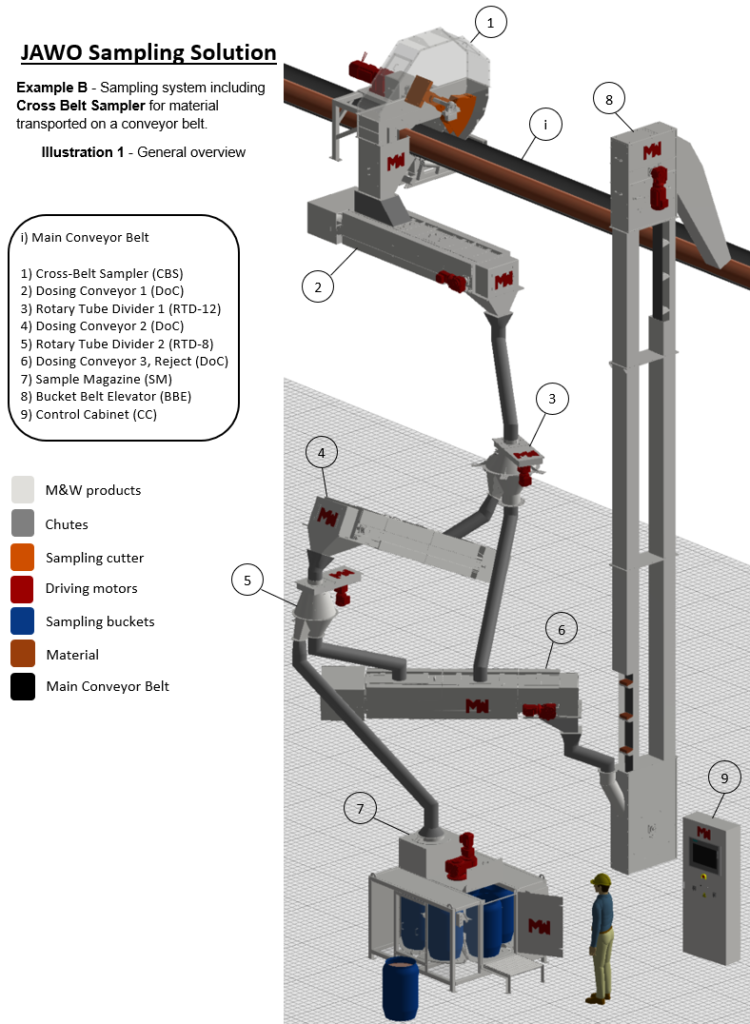

JAWO Sampling Solution – Cross Belt Sampler

How to do representative sampling of bulk material from a conveyor belt?

To ensure a representative sampling of bulk material from a conveyor belt, the Cross Belt Sampler is the answer.

Solution description

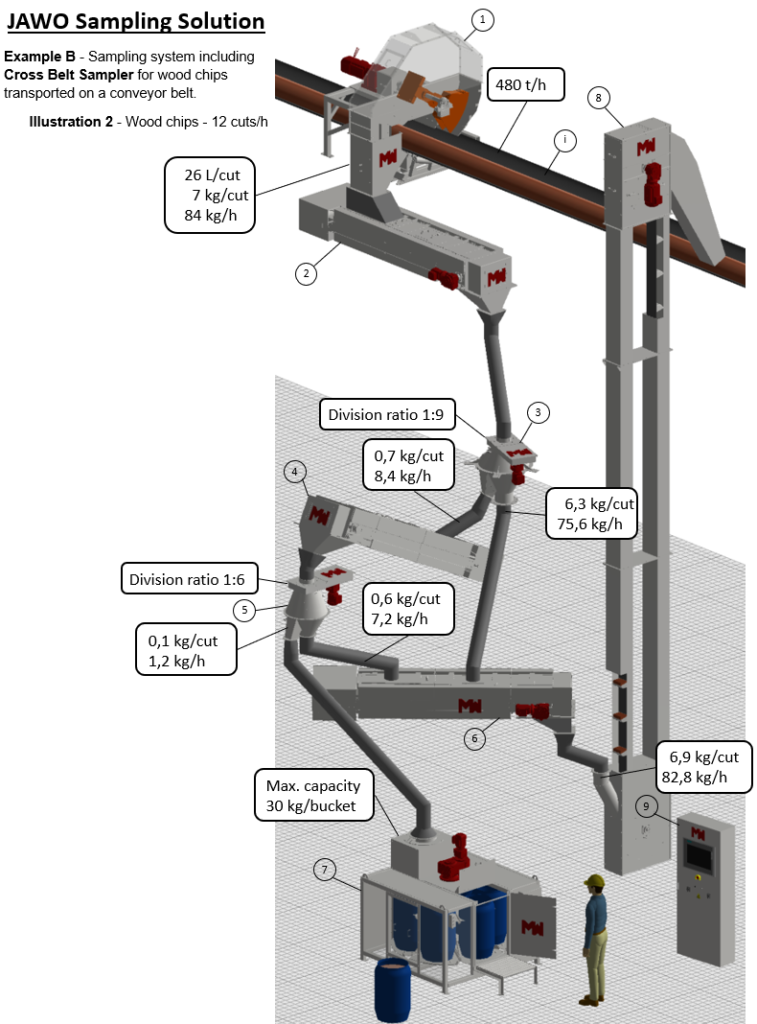

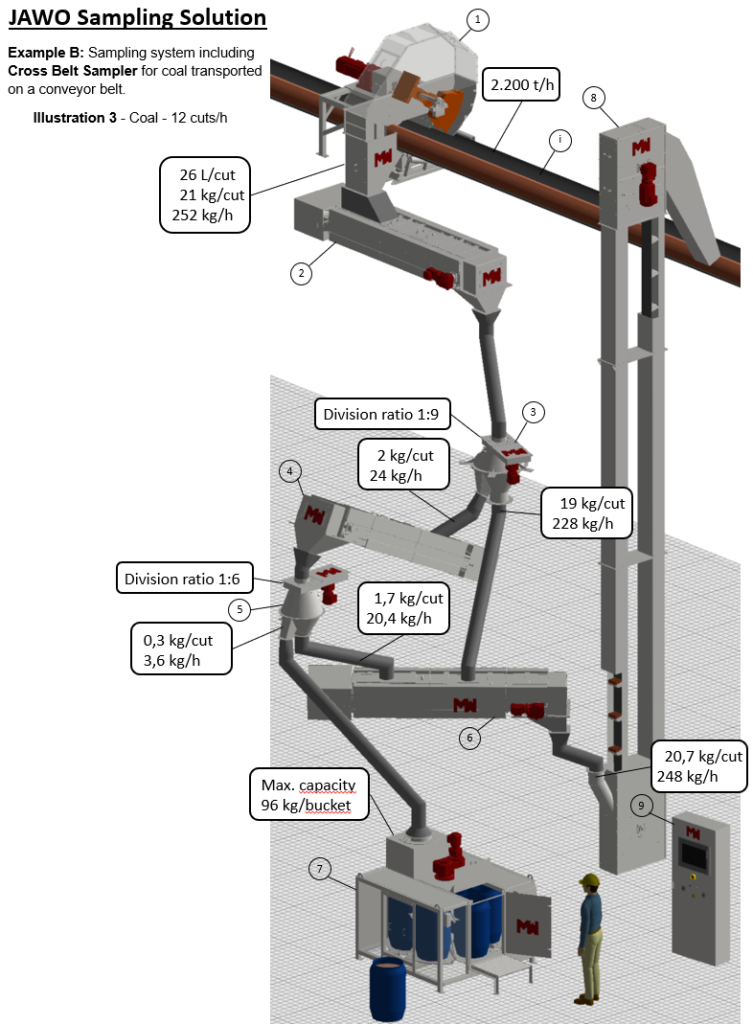

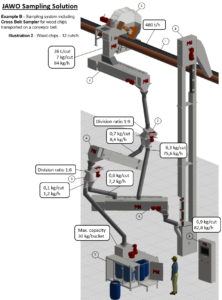

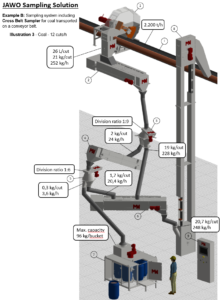

- The Cross Belt Sampler (CBS) is designed to extract increments/cuts from bulk material being transported on a conveyor belt. A representative increment is scooped into the sampling outlet from the conveyor belt in a circular motion by rotation of a sample cutter.

The sampling outlet of the CBS is connected to a Dosing Conveyor by a chute.

- The Dosing Conveyor 1 (DoC) is used to transport and/or dispense the bulk material by a belt. The DoC has a design, which ensures minimum spillage of the material and a correct dosing.

The DoC dispenses the material into a chute, which is connected to a Rotary Tube Divider.

- The Rotary Tube Divider 1 (RTD-12) is designed for a representative division of bulk material. The RTD splits the material stream into A) a sub-sample and B) a reject stream. The reject stream is connected to a DoC (6) by a chute.

The sub-sample outlet of the RTD is connected to a second Dosing Conveyor by a chute.

- The Dosing Conveyor 2 (DoC) transports and/or dispenses the sub-sample outlet from the RTD-12 (3) to a second Rotary Tube Divider by a chute.

- The Rotary Tube Divider 2 (RTD-8) divides the sub-sample from RTD-12 even further with the same representative division mechanism as for the RTD-12. The reject stream is connected to the DoC (6) by a chute.

The sub-sample outlet of the RTD is connected to a Sample Magazine by a chute.

- The Dosing Conveyor 3 (DoC) transports and/or dispenses the reject stream of bulk material from the RTD-12 (3) and RTD-8 (5) to the Bucket Belt Elevator by a chute.

- The Sample Magazine (SM) is designed to automatically fill sample buckets with representative samples of bulk material thereby ensuring a composite sample. The SM acts as a storage device since it has multiple buckets installed inside on a carousel. The SM is designed to prevent contamination and moisture gain and loss of the gathered samples.

- The Bucket Belt Elevator (BBE) lifts the reject stream back to the main conveyor belt by means of buckets. The buckets are attached to a belt that pulls them around.

- All the above equipment requires a Control Cabinet (CC) that controls, powers and protects the JAWO Sampling machines. The CC is also the interface for the operator and can serve as a junction box for all power and signal cables.