TRS Product Brochure

To find out more about our Twin Roll Shredder (TRS) please feel free to download product brochure:

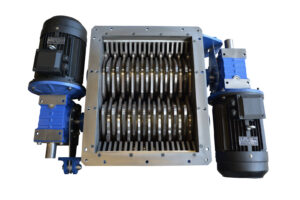

The Twin Roll Shredder (TRS) is designed for shredding of soft and medium-hard materials – dry or slightly wet and semi-sticky. For materials such as wood chips, waste wood, cardboard, plastics, coal, electro-scrap and some metal waste like milling waste.

The Twin Roll Shredder can be used as a primary, secondary or even tertiary crusher.

The Twin Roll Shredder (TRS):

To find out more about our Twin Roll Shredder (TRS) please feel free to download product brochure:

The TRS consists of an inlet opening, two counter-rotating roll shafts each with independent gear driven motors and a base frame. The material is by gravity fed through a hopper or duct into the top inlet opening, from where it is drawn into the shredding zone, by the two counter-rotating roll shafts. The twin rolls can be controlled individually or synchronously.

To ensure that the particles exiting the shredding zone are small enough a sieve is placed underneath the roll shafts. If a particle cannot exit through the sieve, it is forced back into the inlet of the counter-rotating rollers for further shredding.

The design ensures a unique self-cleaning action.

Options

Nota Bene

The rollers come in a variety of geometries equipped with bigger or smaller knives and in a variety of material (Hardox 600, chromium, manganese, or tungsten carbide). Roll geometry, material and rotation speed can be configured depending on the specific material requirements.