SMX Product Brochure.

To find out more about our Screw Sampler

Mixing Tank (SMX) please feel free to

download product brochure:

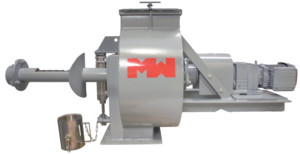

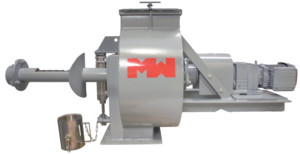

The Screw Sampler Mixing Tank (SMX) is designed to create an average composite sample from continuous or intermittent increment extraction of dry non-sticky powdered free-falling material from a chute or in a silo.

The SMX is the standard in many cement plants where extraction and integrated mixing is required. The mixing function of the SMX provides for more well-mixed samples compared to the SCR.

To find out more about our Screw Sampler

Mixing Tank (SMX) please feel free to

download product brochure:

The SMX is driven by a geared motor coupled to a transport screw which is placed inside a fixed tube with a opening allowing the free falling material to enter.

The SMX can be mounted in chutes (rectangular or circular) with maximum inclination of 30°.

The screw continuously transports the extracted material into a mixing tank, where it is mixed by impellers attached to an extension of the screw conveyor shaft.

The mixed sample is extracted manually from the mixing tank into a sample container (volume app. 1.4 l).

This mixer tank design ensures that the sampled material at all times represent an optimal average of the material captured by the screw intersect of the primary falling flow.

The mixing tank is provided with an observation window and has an overflow to safeguard against overfilling. Excess sample material is returned to the main material stream by gravity.

The sampler is made from mild steel and painted according to M&W standard colour RAL 5010, topcoat unless agreed otherwise. Polyester Powder brightness 30.

Options

1. The SMX can be supplied with local control.

2. The SMX is also available with approval for working with ATEX.

3. The motor can be equipped with a frequency converter to enable adjustable speed.

4. As an option the SMX can be supplied in stainless steel AISI304.

5. The mixed test sample can as an option be automatically discharge by use of two air piston cylinders.

Nota Bene 1

The quotation does not include a local control panel and reject pipe.

Nota Bene 2

The SMX operates under the assumption that the cross-section of the falling material is of uniform composition, allowing it to be sampled by a linear transect only. The degree to which a screw sampler can obtain a fit-for-purpose representativity status is dependent upon the specific heterogeneity characteristics of the material sampled. M&W offers customers a facility for quantitative assessment of the performance following one or several types of analyses such as variographic or replicate analysis based on the customer’s material.