Mechanical Engineering.

Mechanical Engineering (ME) is at the core of M&W, especially within the disciplines of mechanics, dynamics, thermodynamics and structural analysis.

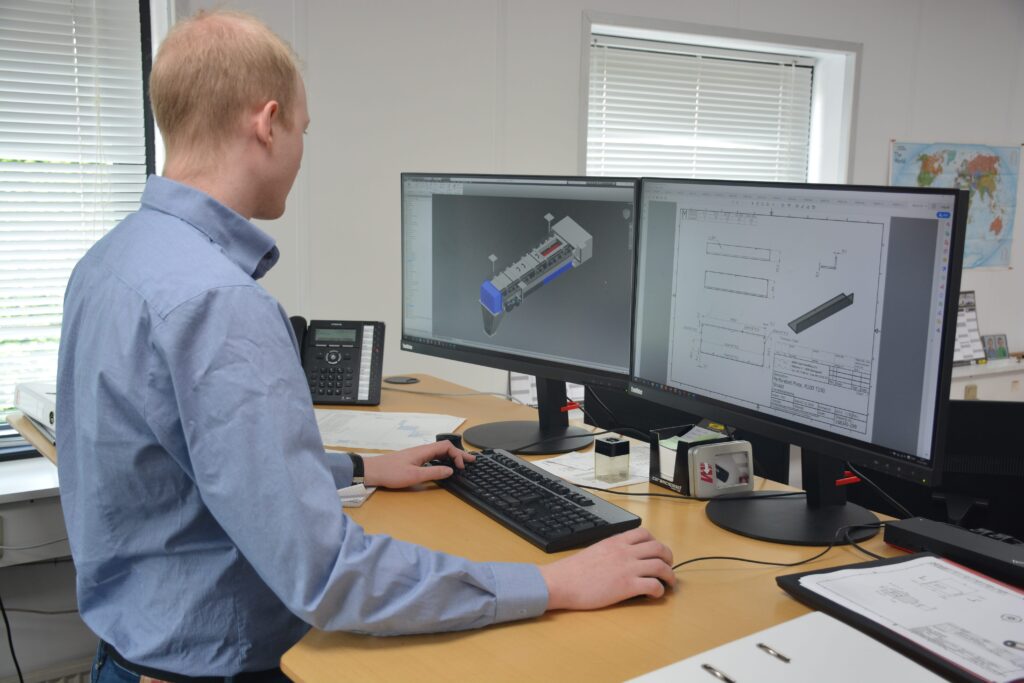

Mechanical Engineering Team

M&W has a dedicated team of mechanical engineers that design, engineer, build, test and document the product/solution. The design is either based on our standardised concepts which takes customers specifications into account or can be a development of a prototype.

M&W offers an A to Z solution, and thus after the engineering has been performed, a dedicated team of inhouse machine operators, metalworkers and blacksmiths ensure the entire mechanical production.

After production, the M&W mechanical and electrical engineers test the entire product/solution before shipment. As per requirement, a factory acceptance test (FAT) is performed before shipment.

Engineering Services

Electrical Engineering is also a vital part of Mark & Wedell’s services. The electrical engineering team is responsible for designing and implementing electrical systems and components, that work in tandem with the mechanical components. They work on the control systems that allow for precision sampling, analyzing and recording data, and monitoring the sampling process.

M&W has extensive experience in designing and manufacturing mechanical and automated sampling equipment for a wide range of industries, including mining, cement, and chemical. Their sampling equipment is designed to meet industry standards and is reliable, accurate, and easy to use.

The electrical engineering team plays a key role in ensuring that the sampling process is fully automated, making it easy for operators to use and ensuring that the sample collected is accurate and representative.

One-Stop-Shop

From designing and engineering to manufacturing, testing, and installation, M&W offers a one-stop-shop for mechanical, electrical and automated sampling equipment. Their dedication to quality and customer satisfaction ensures that they remain a trusted partner in the industry.