GOLS Product Brochure.

To find out more about our Gyratory On-Line Screen (GOLS) please feel free to download product brochure:

To find out more about our Gyratory On-Line Screen (GOLS) please feel free to download product brochure:

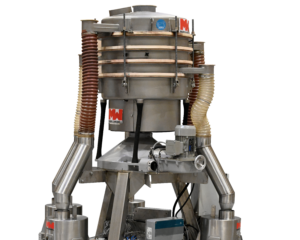

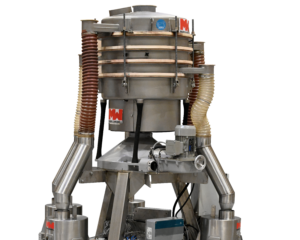

The Gyratory On-Line Screen (GOLS) is designed for precise screening and subsequent measurement of particle size distribution in sample material based on gyratory motions. The GOLS works well with dry, dusty and grainy materials such as granules and different types of ore.

The Gyratory On-Line Screen (GOLS):

Find more of Mark & Wedell JAWO Sampling’s screening equipment here:

To find out more about our Gyratory On-Line Screen (GOLS) please feel free to download product brochure:

To find out more about our Gyratory On-Line Screen (GOLS) please feel free to download product brochure:

The Gyratory On-Line Screen (GOLS) is designed for precise screening and subsequent measurement of particle size distribution in sample material based on gyratory motions.

The GOLS works well with dry, dusty and grainy materials such as granules and different types of ore.

It does so electronically in real-time without the need for manual weighing and “writing weights down on paper” as the output data are automatically sent to the data management system.

It can used as an integral unit in a sampling system or as a stand-alone gyratory screen.

The GOLS consists of an inlet, a screen section, a base frame, and multiple outlet sections. The screen area accommodates multiple different screens, and with each screen there is an opening allowing for material flow towards the outlets. The base frame holds and drives the mechanism through vibrations. The outlet sections hold, measure, and distribute the fractionated sample material.

The sample material is fed by gravity into the inlet, from where it is drawn through the screens. The screens fractionate the material, as each screen only allows passage for particles with a diameter below a certain limit.

When the material is sorted, it is fed into the tanks through flexible tubes. Here it is weighed, and when the weight limit is reached, a knife gate valve opens, and the material is sent through to the outer system. Weight information – hence particle size distribution – is electronically transferred to the data management system.

Material type: Dry, dusty, powdery and grainy materials.

Drive unit: Gear motor.

Voltage: 400/230 V – 50 Hz or as required.

Sensors: Inductive sensors, load cells.

Indicative Dimensions (LxWxH): 1650x1650x2300 mm.

Indicative weight: 1000 kg.

Screen options: Number of screens and screen sizes depends on customer requirements and relevant standards.

Housing material: Stainless Steel AISI 304/316 and/or painted galvanized mild steel.

Material flow: Depends on sample material.

Options

1. The Gyratory On-Line Screen can be delivered as a standard Gyratory Screen with or without the On-Line option.

Nota Bene

The GOLS comes with a variety of screen options. The number of screens, screen material and screen mesh size can be made to fit customer requirements and relevant standards. The overall dimensions and number of outlets of the GOLS differ with the number of screens.

Cookie Settings is not available. Cookie Consent is disabled or is just disabled for your country.