CBSw Product Brochure.

To find out more about our Cross-Belt Sweeper (CBSw) please feel free to

download product brochure:

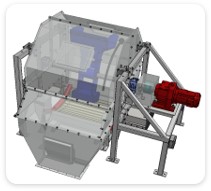

The Cross-Belt Sweeper (CBSw) is designed to remove tramp metal from bulk material being conveyed on a conveyor belt. Without belt stoppage The CBSw will automatically remove tramp metal by a detection system with a minimal waste of usable bulk material.

The Cross-Belt Sweeper (CBSw):

Find more of Mark & Wedell JAWO Sampling’s materiale transfer equipment here:

To find out more about our Cross-Belt Sweeper (CBSw) please feel free to

download product brochure:

The Cross-Belt Sweeper (CBSw) is designed to remove tramp metal from bulk material being conveyed on a conveyor belt.

Without belt stoppage The CBSw will automatically remove tramp metal by a detection system with a minimal waste of usable bulk material.

The CBSw can be integrated on any belt size, speed, and construction. The CBSw is a cost-effective solution that increases uptime in your operation.

The unit consists of a rotating counter-weighted sweeper which moves in a 360-degree rotation perpendicular to the material direction. The sweeper is driven by a gear brake motor and the conveyor belt is supported and guided by a pair of inclined rollers or guiding plates. The cover house is equipped with hatches allowing easy inspection, cleaning, and maintenance.

When automatically triggered, the cutter is accelerated by the electric motor. It sweeps through the material stream on the conveyor belt in a circular motion, following the supported shape of the belt.

The CBSw is delivered with either a local control unit or/and is controlled by a M&W central control cabinet depending on concept and local conditions. The M&W central control cabinet consist of motor control center, circuit breakers, PLC-system and man-machine interface.

Options

The M&W central control cabinet can exchange signals with the client’s control system.

Nota Bene 1

Our conveyor belt transports about 6-8 ton of material every hour. Tramp metal is a well-known and very real threat to our uptime. In the two years since we acquired the CBSw from Mark & Wedell it has been triggered up to 450 times daily.

At this point, there can be no doubt that the CBSw has saved our crushers from expensive damage many times over, and we have had a return on investment in less than 6 months.

– Industrial Automation Manager at Etex

Cookie Settings is not available. Cookie Consent is disabled or is just disabled for your country.