Boliden Port Pori Sampling Plant – Copper/Nickel Concentrate – 2022 .

Boliden and Mark & Wedell in front of 40 metres tall sampling building

Boliden Sampling Head and Project Leader in front of primary sampler (CSS)

Secondary sampler buillt in directly on dosing conveyor

Seconrdary sampler buillt in directly on dosing conveyor

Dividers and transportation units

Jaw crusher including screens and hopper

Jaw crusher including screens and hopper

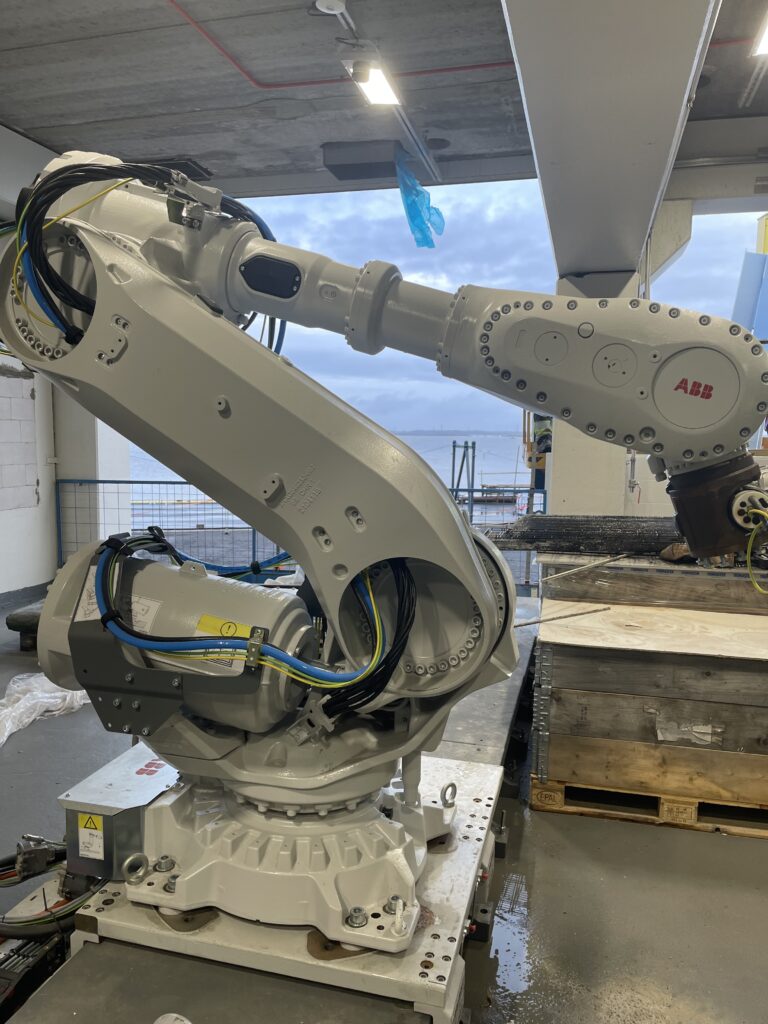

Robotic solution for handling samples

Primary sampler built onto dosing conveyor

M&W JAWO Sampling has supplied a complete sampling solution for automated sampling of copper and nickel concentrate at the Port of Pori harbor facilities where Boliden receives the material by ship from all over the world. The sampling solution was part of an investment in upgrading infrastructure (weighing and sampling facility and new warehouse) at Port of Pori to improve its smelting operations in Harjavalta (the largest nickel smelter in Western Europe).

By installing this receiving and sampling facility, Boliden is now able to take automated representative samples upon arrival and before the material reaches the smelter in Harjavalta.

Around 100 ships each containing 10 to 12 kilotonnages of concentrate arrive each year at the Port of Pori. The M&W JAWO Sampling solution enables a representative sample of only 2 kg from a total increment of 500 tonnes being sampled during 30 minutes. Hence 20 samples of 2 kg represent the total load.

The M&W JAWO sampling solution is located in a newly built 40 meters tall sampling building with 5 floors only for the purpose of hosting the weighing, sampling, moisture determination and sample preparation processes.

It contains a primary and a secondary sampler, an almost 20m tall bucket belt elevator, two jaw crushers both with built-in screens for screening and dosing (One with the weight of 4.4 tonnes!), vibration feeders, dosing conveyors, rotary tube dividers and a sampling magazine.

A robotic arm takes each sample and dry it in the drying ovens.

This was the 8th sampling solution supplied to the Boliden group by M&W JAWO Sampling.

M&W JAWO Sampling has supplied a complete sampling solution for automated sampling of copper and nickel concentrate at the Port of Pori harbor facilities where Boliden receives the material by ship from all over the world. The sampling solution was part of an investment in upgrading infrastructure (weighing and sampling facility and new warehouse) at Port of Pori to improve its smelting operations in Harjavalta (the largest nickel smelter in Western Europe).

By installing this receiving and sampling facility, Boliden is now able to take automated representative samples upon arrival and before the material reaches the smelter in Harjavalta.

Around 100 ships each containing 10 to 12 kilotonnages of concentrate arrive each year at the Port of Pori. The M&W JAWO Sampling solution enables a representative sample of only 2 kg from a total increment of 500 tonnes being sampled during 30 minutes. Hence 20 samples of 2 kg represent the total load.

The M&W JAWO sampling solution is located in a newly built 40 meters tall sampling building with 5 floors only for the purpose of hosting the weighing, sampling, moisture determination and sample preparation processes.

It contains a primary and a secondary sampler, an almost 20m tall bucket belt elevator, two jaw crushers both with built-in screens for screening and dosing (One with the weight of 4.4 tonnes!), vibration feeders, dosing conveyors, rotary tube dividers and a sampling magazine.

A robotic arm takes each sample and dry it in the drying ovens.

This was the 8th sampling solution supplied to the Boliden group by M&W JAWO Sampling.