Download our brochure

Get an overview of JAWO Sampling solutions with examples and illustrations for printing or sharing.

• M&W JAWO Sampling Brochure – English version

M&W JAWO Sampling offers a complete range of automated machines, instruments and systems for collecting representative (accurate and reproducible) samples of bulk materials, granules and fines/powders.

In addition, our product range includes sample preparation and analytical equipment – engineered and manufactured for your specific plant and processing requirements.

Get an overview of JAWO Sampling solutions with examples and illustrations for printing or sharing.

• M&W JAWO Sampling Brochure – English version

Feel free to contact us with any questions or specific requirements you may have.

Our team of technical experts is here to assist you with tailored solutions and guidance on our equipment and services.

By using our automated sampling and sample preparation solutions, you gain precise, unbiased, and verifiable data for better business decisions, optimized processes, and improved financial outcomes.

With over 40 years of experience and a complete portfolio of customized sampling solutions, M&W JAWO Sampling helps you to:

Avoid overpaying for incoming materials or underselling your products.

Continuously monitor and optimize your production processes and quality control. Our systems provide the reliable data needed to:

Proactive monitoring and early detection prevent costly problems:

Free your team from repetitive, time-consuming manual sampling tasks. Our automated systems:

Protect your team from the hazards of manual sampling. Our automated systems:

Ensure your products meet contract specifications with documented and traceable sample data. Our systems provide:

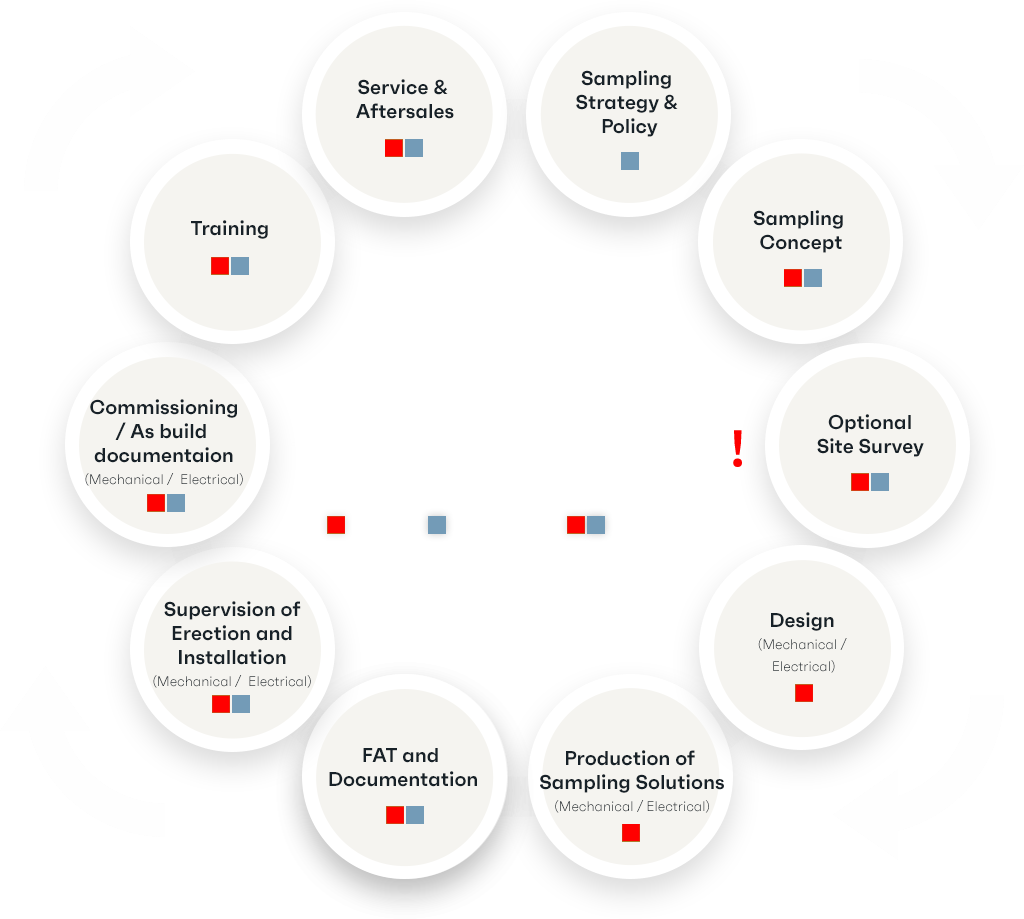

M&W JAWO Sampling is more than a equipment supplier—we are your partner in sampling excellence and tailor-make our systems to your exact needs and plant configuration.

Our complete in-house capabilities include:

We understand that every operation is unique. We listen to your challenges, design solutions that fit your specific needs, and stand behind our work.

Investing in an automated sampling solution from M&W JAWO Sampling will save you money, improve your operations, enhance safety, and give you the data you need to lead with confidence.

You will be assured sampling solutions which produce consistent samples for your quality analysis – accurately and precisely representing the total lot.

Obtaining representative samples of the total lot before analysis is crucial – otherwise, there is little point in having made significant investments in laboratory equipment and analytical competencies.

From the beginning, in1982, M&W JAWO Sampling has been pioneer and led the way in the development, engineering and production of automated sampling equipment and solutions – with over 1,000 projects completed in more than 85 countries around the world

M&W JAWO Sampling equipment and sampling systems operate in accordance with approved international material standards such as ISO, ASTM, GOST, EN as well as DS3077 (2013).

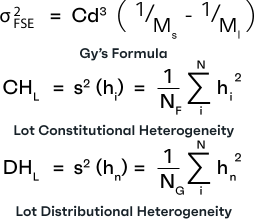

All sampling equipment and solutions aim for compliance with the principles laid down in the Theory of Sampling (TOS) and gives you reliable knowledge of the material properties of your sample such as:

M&W JAWO Sampling has supplied more than 3,000 automated sampling solutions to more than 950 projects in 85+ countries within the mining, mineral processing & metals refining, oil & gas, power and heat generation, cement, fertilizer, recycling and waste handling, building materials, food and pharma sectors.