Maersk Oil & Gas/Aker BP – Devel. of Annulus Pressure Relief System .

In 1995, M&W Engineering was contacted by Maersk Oil & Gas (Total) to come up with a better, safer and more reliable pressure protection system to be used for well stimulation and intervention jobs. Other technologies had proven unreliable and insufficient.

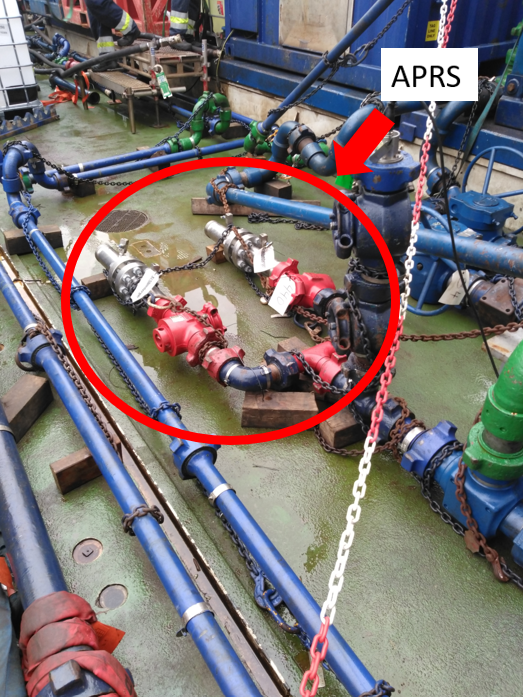

As part of this partnership M&W Engineering developed an entirely new system for oil and gas wells, called the Annulus Pressure Relief System (APRS) based on easy to install and replaceable burst disc technology including all relevant certificates and Type Approval Documentation from DnV. All necessary parts come in robust wooden box and are all continuously re-certificed allowing for one-stop-shop operation.

The first version of the APRS was certified to a working pressure of up to 6,000 psi (413 bar). An upgraded version for working at even higher pressure loads up to 10,000 psi (689 bar) was subsequently developed and DnV certified for Aker BP in 2020.

Ever since the APRS has been used by more than 10 oil and gas companies and service companies such as Shell, BP, Maersk Oil & Gas (now Total), Hess, Halliburton and Schlumberger for 1,000+ well stimulation jobs on – and offshore around the world. It has been widely used in the Danish and British parts of the North Sea, as well as other areas such as Iraq, Kazakhstan and the South China Sea.

Click here to see Type Approval Certificate DNV.

“Maersk Oil has over the years done thousands of stimulations worldwide. We started with what the service companies provided as annulus pressure relief mechanism i.e. the spring operated or Nitrogen operated systems.

However, we were not happy with their performance. The provided systems were not reliable as they went off either at too high or too low pressure. That is why we contacted Mark & Wedell to make the burst disc system. We are very happy with this system.

- It is a good and reliable system. It had never let us down and it is easy to use.

- You can install several M&W APRS systems in parallel, so you can isolate the one that has been blown and continue with backup – fast.

- M&W runs a 24-7 service and ensures day-to-day delivery always with sufficient burst discs in stock.”

Jakob Monberg, Global Well Stimulation Specialist (Total) testimony.

Eric Jacobsen, Senior Well Stimlation Engineer (ex-Hess) testimony.

In 1995, M&W Engineering was contacted by Maersk Oil & Gas (Total) to come up with a better, safer and more reliable pressure protection system to be used for well stimulation and intervention jobs. Other technologies had proven unreliable and insufficient.

As part of this partnership M&W Engineering developed an entirely new system for oil and gas wells, called the Annulus Pressure Relief System (APRS) based on easy to install and replaceable burst disc technology including all relevant certificates and Type Approval Documentation from DnV. All necessary parts come in robust wooden box and are all continuously re-certificed allowing for one-stop-shop operation.

The first version of the APRS was certified to a working pressure of up to 6,000 psi (413 bar). An upgraded version for working at even higher pressure loads up to 10,000 psi (689 bar) was subsequently developed and DnV certified for Aker BP in 2020.

Ever since the APRS has been used by more than 10 oil and gas companies and service companies such as Shell, BP, Maersk Oil & Gas (now Total), Hess, Halliburton and Schlumberger for 1,000+ well stimulation jobs on – and offshore around the world. It has been widely used in the Danish and British parts of the North Sea, as well as other areas such as Iraq, Kazakhstan and the South China Sea.

Click here to see Type Approval Certificate DNV.

“Maersk Oil has over the years done thousands of stimulations worldwide. We started with what the service companies provided as annulus pressure relief mechanism i.e. the spring operated or Nitrogen operated systems.

However, we were not happy with their performance. The provided systems were not reliable as they went off either at too high or too low pressure. That is why we contacted Mark & Wedell to make the burst disc system. We are very happy with this system.

- It is a good and reliable system. It had never let us down and it is easy to use.

- You can install several M&W APRS systems in parallel, so you can isolate the one that has been blown and continue with backup – fast.

- M&W runs a 24-7 service and ensures day-to-day delivery always with sufficient burst discs in stock.”

Jakob Monberg, Global Well Stimulation Specialist (Total) testimony.

Eric Jacobsen, Senior Well Stimlation Engineer (ex-Hess) testimony.