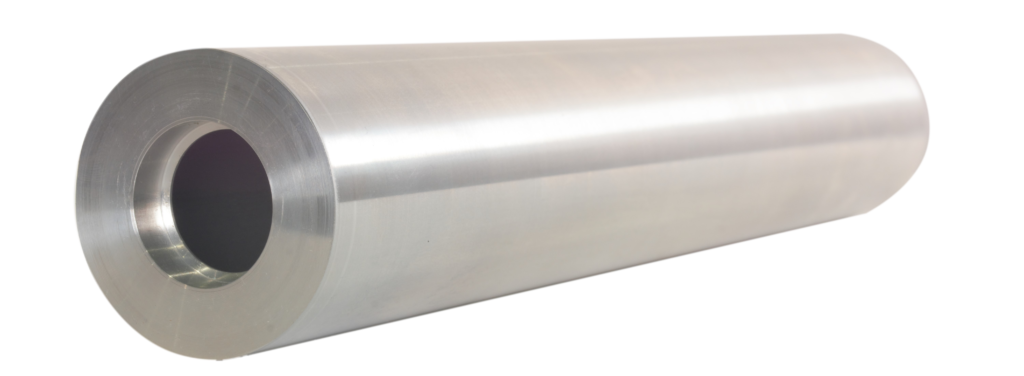

CNC machined Parts

M&W Engineering makes CNC (Computer Numerical Control) machined parts such as metal casings and other parts in variety of dimensions both large and small. We work with a wide variety of materials such as mild steel, stainless steel, aluminum, copper, inconel, hastelloy, duplex, plastic and much more

Our modern CNC machine workshop consists of 15+ machines where the majority are CNC lathing and CNC milling machines supported by 3 tons crane capacity, along with 10+ skilled operators. In addition, we have experienced engineers that work with 3D printing where we can turn your ideas into reality. This allows us to manufacture products under strict requirements from our clients for both small and large orders.

Our machine workshop is part of our general ISO 9001:2015 certification to ensure the very best quality and production standards for our customers. In addition, we have defined standards related to environmental management based on ISO-14001 and regarding a safe and healthy workplace based on ISO 45001 Occupational Health and Safety. Quality management is an integral part of our business model and we have access to state-of-the-art coordinate measuring machines (CMM) required for maintaining high-quality standards through our 3D measurement capabilities for final dimension control and reports made when applicable.

We work with technical drawings in standard formats, such as Inventor, SolidWorks etc. and can work in both 2D and 3D models. We use MasterCam for our production in addition to 2D drawings. This enables our customers to reduce time by sending us instructions and drawings by mail for example as STEP, DWG and DXF files.

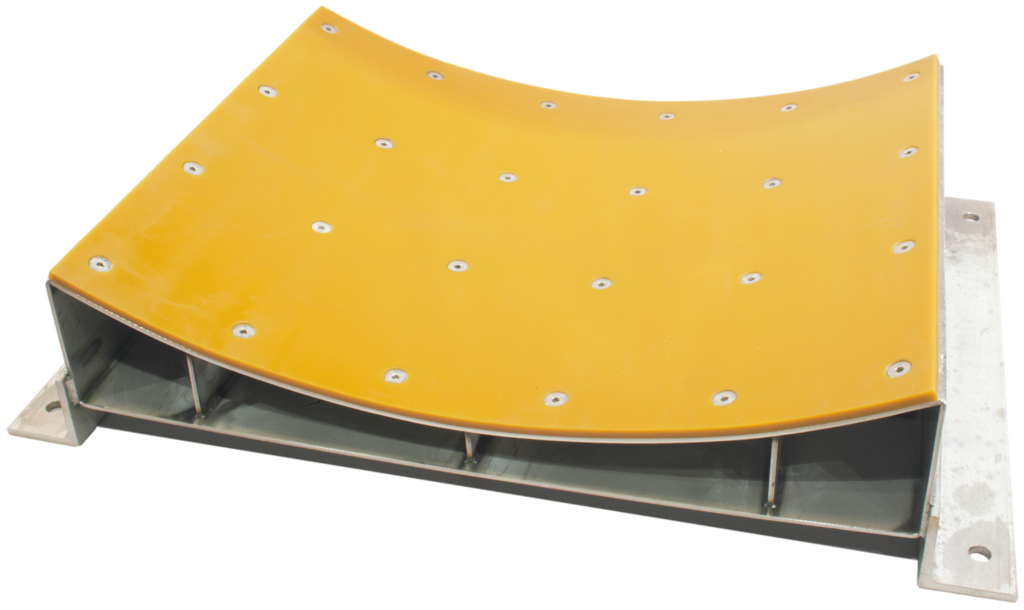

Find more of Mark & Wedell Engineering’s like: Tables for laboratories and process industry