Our Facilities.

We are located in Kvistgaard, 30 km north of Copenhagen, Denmark with 4,000 m2 of facilities including 4 modern production facilities divided between machinery, welding and electrical workshops (3,000 m2) along with our engineering and administrative offices (1,000 m2). We employ 40+ mechanical and electrical engineers, machinists, welders and industrial electricians with our three departments; M&W Jawo Sampling, M&W Big Science and M&W Engineering.

Our engineers primarily work with the development of special machines and measurement instruments. We have a deep insight in analysis of mechanical, electrical and thermodynamic systems. Furthermore we are knowledgeable in measurement theory and techniques. Finally, we are accustomed to provide extensive documentation and quality control.

Choose sector

Machine workshop

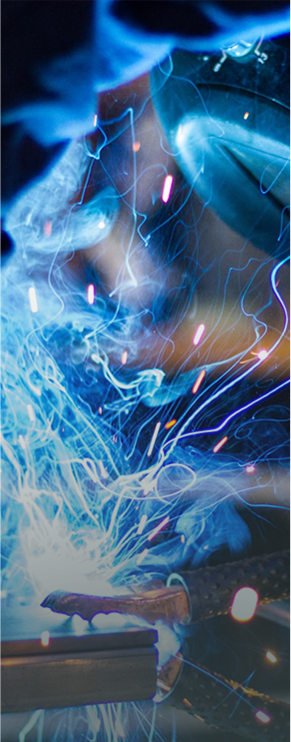

Welding Workshops

Electrical workshop

Mechanical engineering facility

Electrical engineering facility

Inspection and quality control

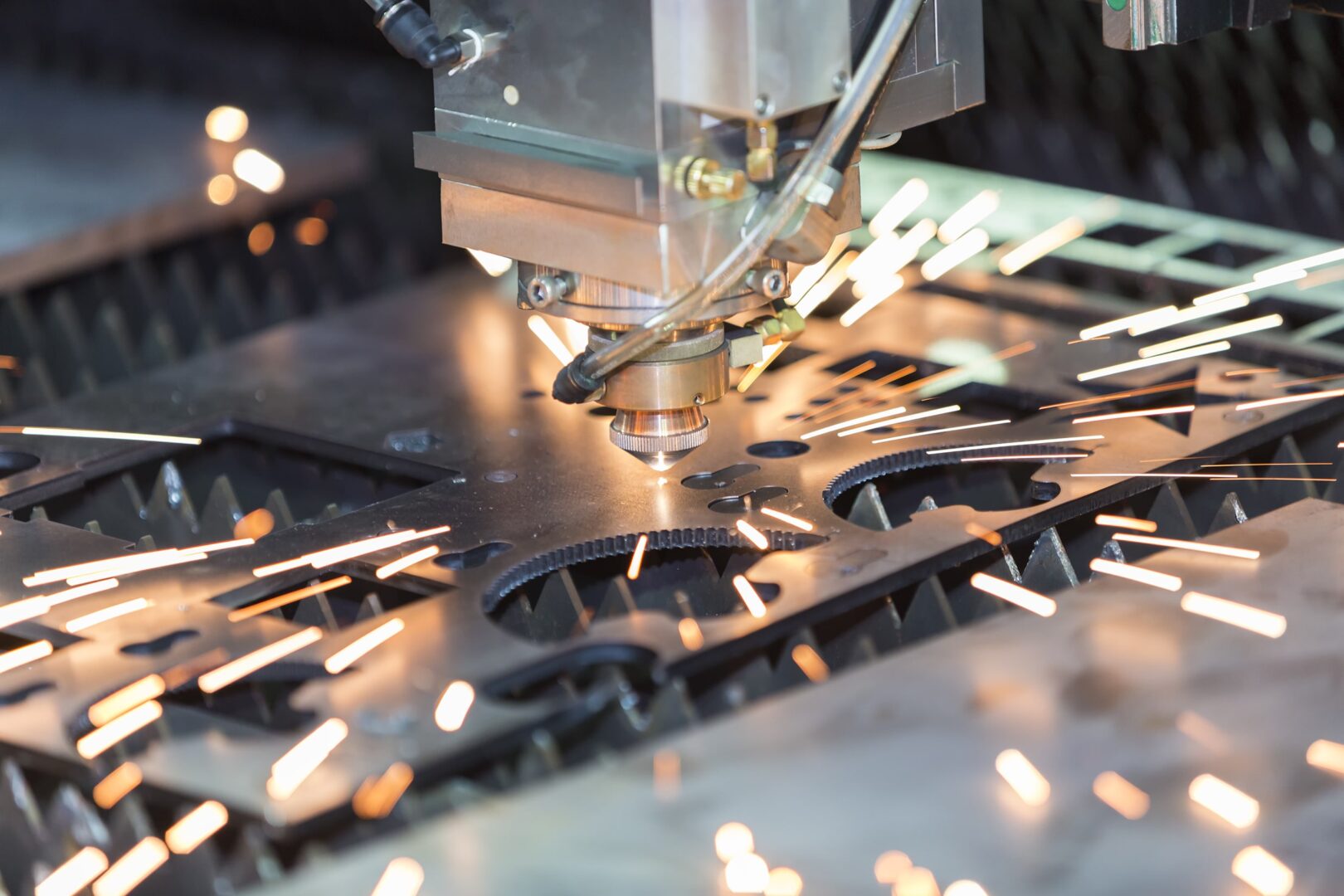

Machine workshop

M&W Engineering - Machine Workshop

Our machine workshop consists of 15+ machines where the majority are CNC lathing and CNC milling machines supported by 3 tonnes crane capacity, along with 10+ skilled operators. In addition, we have experienced employees who work with 3D printing where we can turn your ideas into reality. This allows us to manufacture products under strict requirements from our clients for both small and large orders

Other machinery

We have 4 large column drills and grinding machinery which can handle difficult materials and tasks

Measurement device

M&W Engineering is ISO 9001:2015 certified and complies with ISO 14001 and ISO 45001. Quality management is an important part of our business model and through the Hexagon Manufacturing Intelligence Global S measuring machine we can ensure dimensional measurements and inspection tasks.