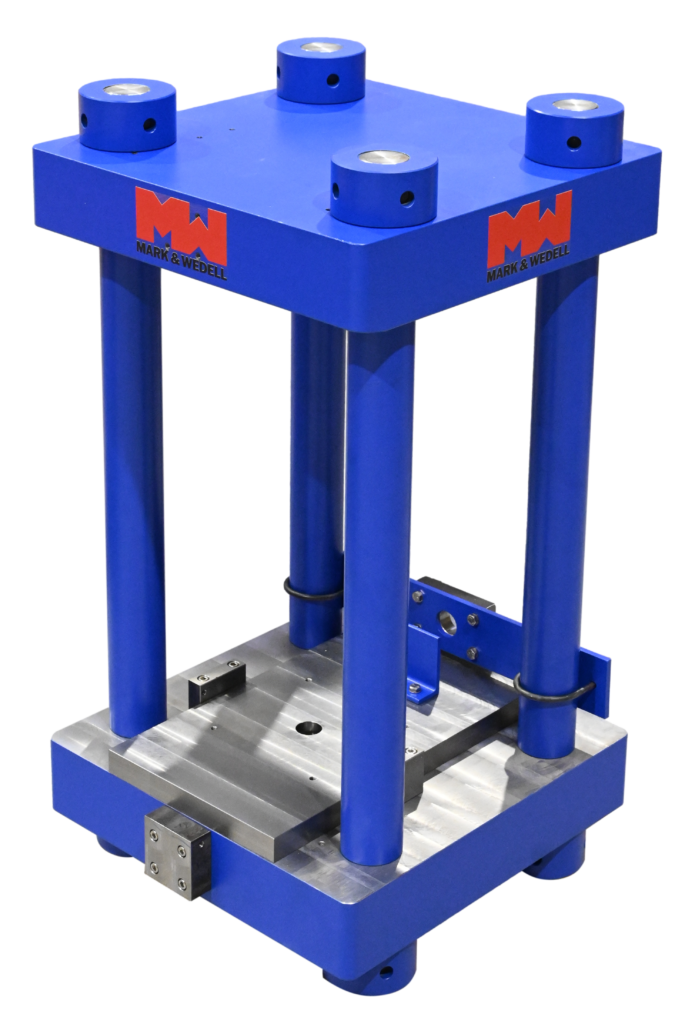

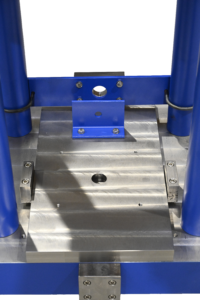

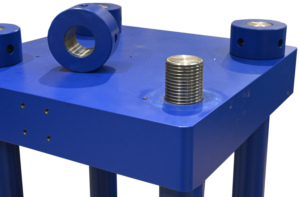

Engineered, Machined, Welded, Painted and Assembled

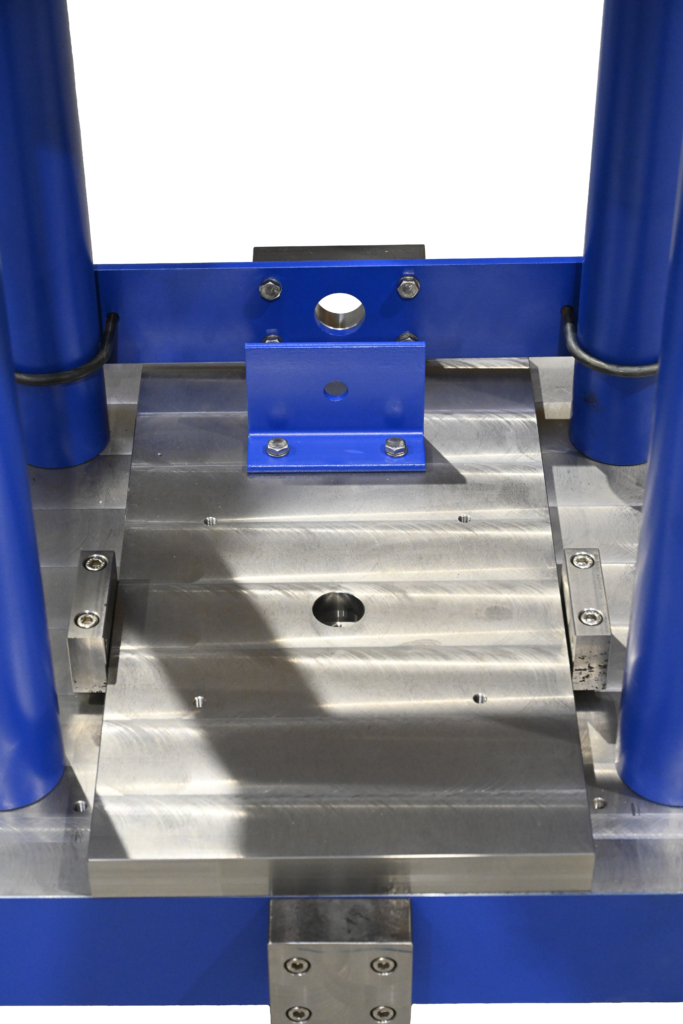

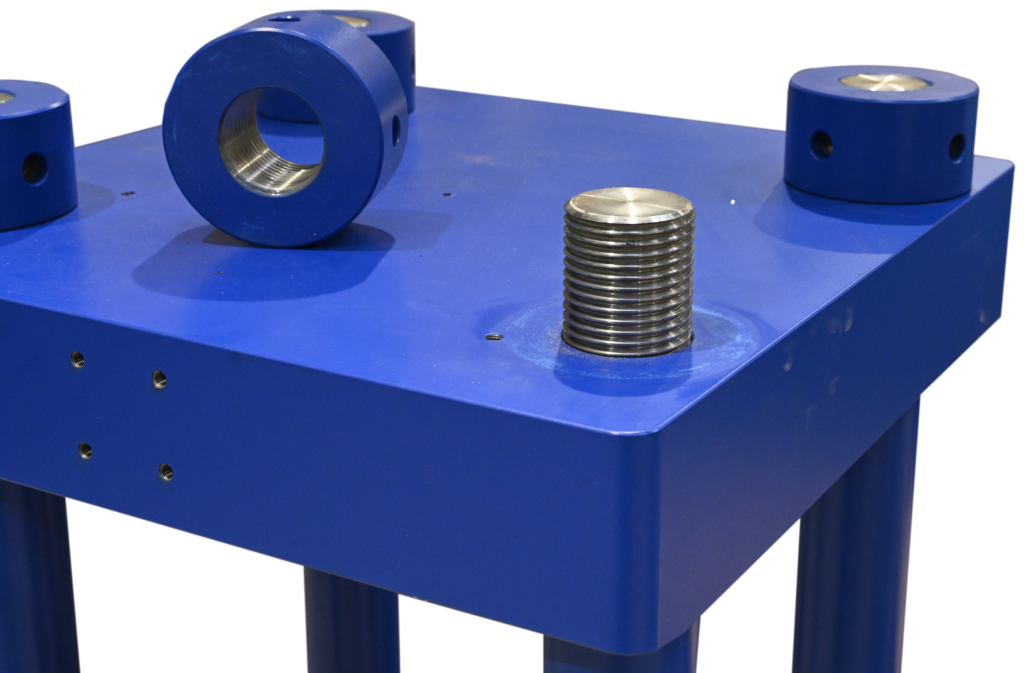

M&W Engineering makes CNC machined parts, 3D print, Steel works, welding, surface treatment and in addition electrical assembly and test for large and small parts. We work with a wide variety of materials such as mild steel, stainless steel, aluminum, copper, pom, plastic and much more.

In this business we often start in an early phase of the project where our sales/mechanical engineer defines the concept, scope, functionality, and budget. A typical scope after order includes : Engineering, approval of drawings/functionality, production, surface treatment, assembly and FAT. If electrical switches and/or control is included, we also test this. During FAT the customer often attend for inspection and approval. After shipment we can also perform the mechanical and electrical installation on site and perform a final Site Acceptance Test. If there is a desire for periodic maintenance and service, we are happy to offer this either as an ad hoc service or as a 3-5 year frame agreement.

Our highly skilled and experienced work force that consist of Mechanical and Electrical engineer, machine workers, fitters and electricians assemble and test the product according to customer specifications and internal procedures. Aftersales services can also be performed.

Our assembly work is part of our general ISO 9001:2015 certification to ensure the very best quality and production standards for our customers. In addition, we have defined standards related to environmental management based on ISO-14001 and regarding a safe and healthy workplace based on ISO 45001 Occupational Health and Safety. Quality management is an integral part of our business model and we have access to state-of-the-art coordinate measuring machines (CMM) required for maintaining high-quality standards through our 3D measurement capabilities for final dimension control and reports made when applicable.