What does it do?

The Eccentricity Tester (ET) is used to test the eccentricity of the sockets welded on to the transport pipes. This is required to avoid the Pulverized Fuel Sampler PFS/PFSA from getting stuck on the inside wall of the transport pipe during sampling. The ET test if the space inside the transport pipe is sufficent for a full rotation of the PFS/PFSA.

In order to avoid the PFS and PFS-A-SL from getting stuck on the inside wall of the fuel pipe during sampling, the free space for rotation inside the fuel pipe has to be tested. The tool is basically testing the eccentricity of the sockets welded on to the fuel pipes

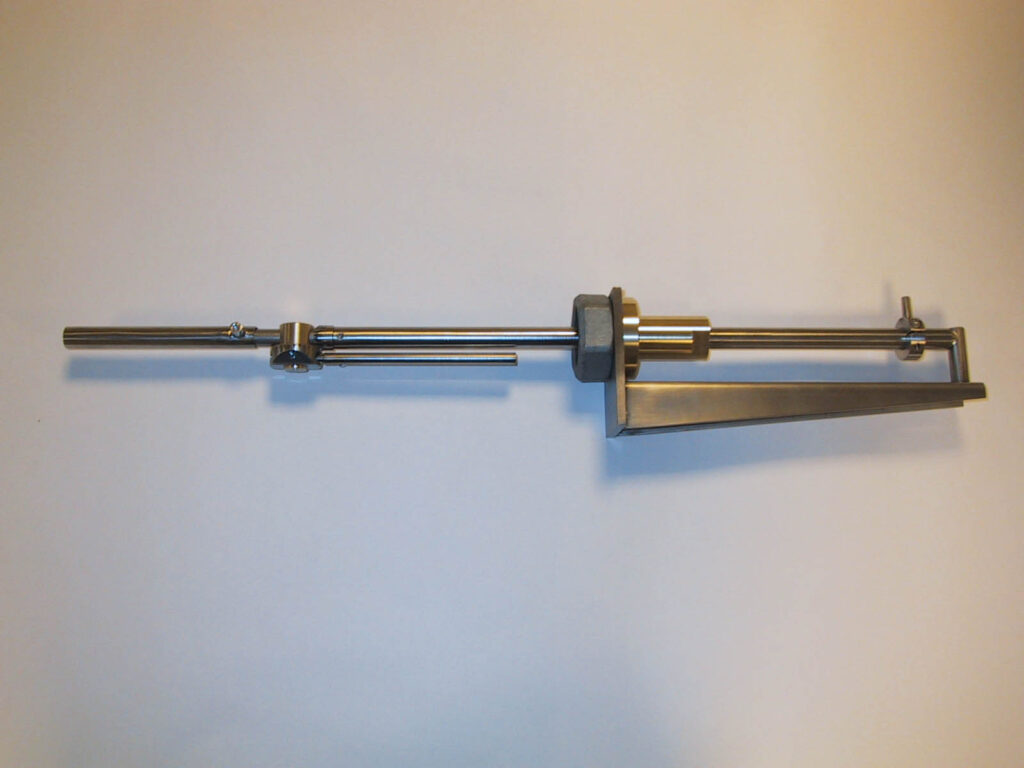

The head of the tool is inserted through the socket and into the fuel pipe until it reaches the opposite inner wall. The arm is rotated by turning the small handle at the rear end of the lance. When a full rotation is performed your have proved that the installation of the Dustlees Connection will be sufficiently accurate to allow a free rotation of the PFS and PFS-A-SL.

How does it do it?

Before the DC is installed, the head of the ET is inserted through the socket and into the transport pipe until it reaches the opposite inner wall. The arm is then rotated manually by turning the small handle at the rear end of the lance. If a full rotation of the ET can be performed without hitting the wall, the socket has been correctly mounted. The DC can now be installed and the PFS/PFSA can now safely and effectively be used for sampling.

What are the technical details?

Details to follow..